Two MTU LNG engines power a special shallow-water push boat

Rolls-Royce and Canadian vessel designers Robert Allan introduced the world’s first LNG-powered shallow-water push boat. The project is the result of a joint development for environmentally friendly and climate-friendly transportation on inland waterways. At the International Workboat Show in New Orleans, classification society DNV GL gave its ‘Approval in Principle’ to the new design. […]

Rolls-Royce and Canadian vessel designers Robert Allan introduced the world’s first LNG-powered shallow-water push boat. The project is the result of a joint development for environmentally friendly and climate-friendly transportation on inland waterways.

At the International Workboat Show in New Orleans, classification society DNV GL gave its ‘Approval in Principle’ to the new design. Powered by two MTU 8V4000M55RN natural gas engines from Rolls-Royce and designed for use on inland waterways, the push boat is more cost-effective to operate, and produces less pollutants and climate-unfriendly exhaust gases than vessels with conventional propulsion systems.

ROLLS-ROYCE AND SVITZER WORKING TOGETHER

The design of the shallow-water push boat

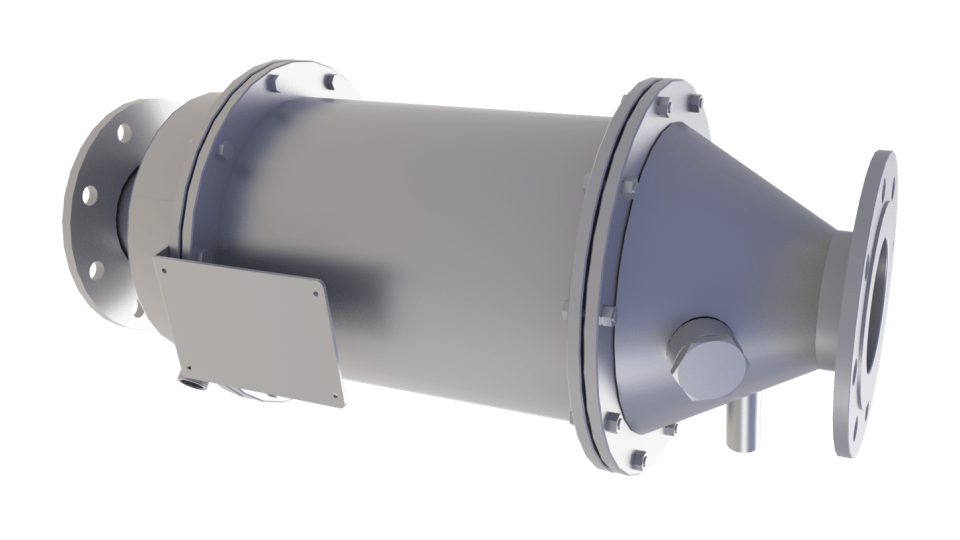

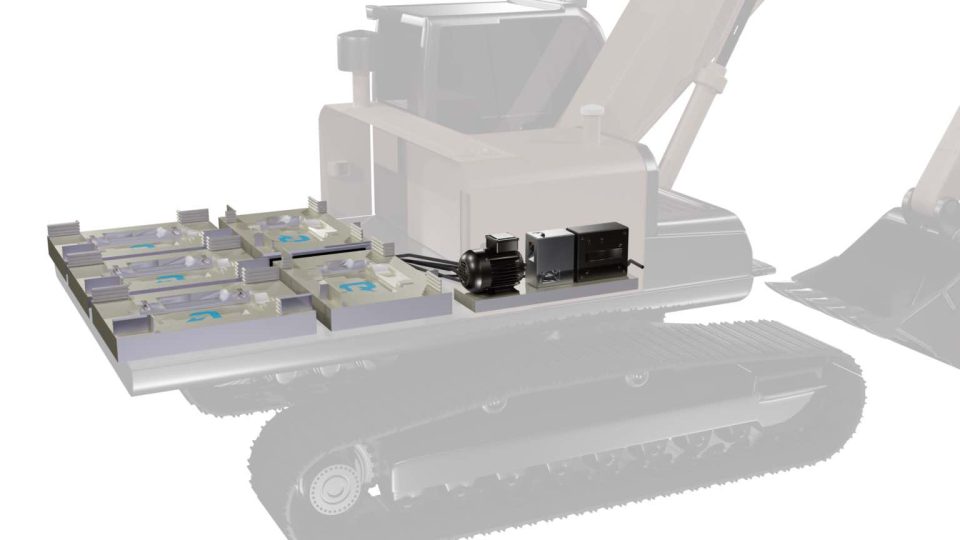

Rolls-Royce and Robert Allan collaborated to design the gas-powered shallow-water push boat based on the proven Robert Allan RApide 2800-Z2 design which is already used on some diesel-powered vessels on the River Amazon. The vessel design was specially modified for LNG to accommodate the two 746 kW MTU 8V4000M55RN engines (complete with IMO Tier III emission control systems) and the entire LNG supply system– also available from Rolls-Royce – as well as the gas control and safety systems and the overall vessel control system.

MTU MARINE HYBRID AT CANNES YACHTING SHOW

The hull – externally unchanged – was redesigned to accommodate the 70 cubic meter gas tank as well as the usual engine accoutrements, and to provide crew with a pleasant working environment. The lower crew cabins, saloon and galley were moved up one level, and the deckhouse was enlarged.

Environmentally friendly LNG

LNG (liquefied natural gas) is a fuel now gaining traction in maritime circles, enabling operators to reduce emissions that are harmful to the environment and to the climate. LNG engines produce no particulate whatsoever, emitting significantly less NOx than diesel engines, and are more climate-friendly overall. DNV GL expects natural gas to cover over 40 to 80 percent of all vessel propulsion power requirements by 2050.