BBA and Hatz registered 69,000 hours

Possible record: BBA pump with Hatz engine operated for 69,000 hours BBA and Hatz scored 69,000 hours. That alone is a very long period of time, but it becomes even bigger when the context is drainage pumps. These machines are typically operating almost constantly. But 69,000 hours straight is quite an impressive achievement nontheless. BBA, […]

Possible record: BBA pump with Hatz engine operated for 69,000 hours

BBA and Hatz scored 69,000 hours. That alone is a very long period of time, but it becomes even bigger when the context is drainage pumps. These machines are typically operating almost constantly. But 69,000 hours straight is quite an impressive achievement nontheless.

BBA, manufacturer of water, sludge and concrete pumps, has been working closely together with the engine manufacturer Hatz since the early 1970s, and fits its autonomously operating drainage pumps with 1D Supra diesel engines from the German company.

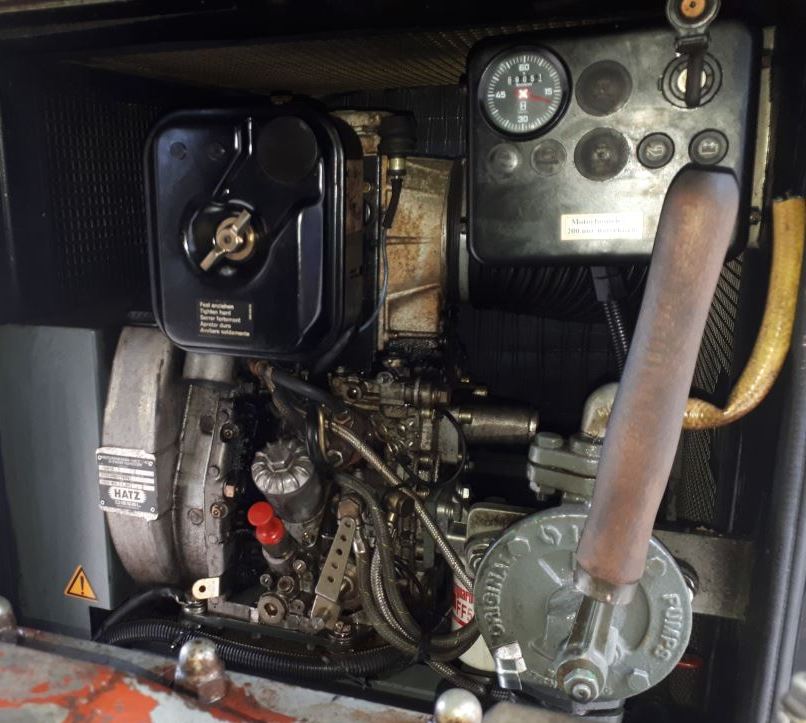

A look at the protagonist

A BBA drainage pump from 2004 that has been in operation at a company for well drainage is the protagonist of this surprising achievement. Such pumps usually operate around the clock with an average total operating time of 5,000 hours per year. For this particular mention, together with a Hatz 1D series engine, the total hypothetical operating time was between 25,000 and 35,000 hours.

In the past, well maintained pumps have even held out for up to 45,000 hours. But this particular pump operated for far longer without any technical problems. The engine was only replaced in October 2018 once its counter had reached 69,000 hours of operation. The manufacturer underlines that it was for safety, not because it was defective.

When asked about the secret to this possibly record-breaking number of operating hours without engine replacement, the operator replied: «Simply change the oil and oil filters in good time, regularly pay attention to good tappet clearance and occasionally fit a new injector. Also, we always keep the engine speed to the factory setting».

What 69,000 hours mean

It is worthwhile placing 69,000 operating hours into relation: 69,000 hours amount to over eight years. At an engine speed of 1,500 revolutions per minute, this engine’s crankshaft has rotated more than six billion times without replacing the bearings. If we were talking about the same number of operating hours on a car, this would amount to a distance of almost five million kilometres at an average speed of 70 kilometres per hour.

A look at the co-protagonist

The Hatz D series engine (1D81Z) is equipped with direct injection. This is a rarity in industrial diesel engines of this power category (10.3 kW). This technology ensures a fuel consumption of around just one litre per hour of operation. In comparison, an engine of the same power category with indirect injection requires around 15 percent more fuel. According to Hatz, with an assumed service life of 30,000 operating hours, the Hatz 1D81Z requires around 4,500 litres of fuel less than engines with indirect injection. This fuel saving corresponds roughly to a cost saving of 5,000 euros.

HATZ CHOSE HANS WEGMULLER AS THE REPRESENTATIVE IN SWITZERLAND