CJC cares about fine filtration

CJC designs and manufactures Oil Filtration solutions for removal of particles, water, acidity and oil degradation products (varnish) from hydraulic oils, lube oils, gear oils, diesel fuels etc

The Danish CJC, initials of the founder Carl Christian Jensen, has been operating in a market niche for about sixty years (HERE, an example from Parker Hannifin). Let’s hear from the subsidiary Karberg & Hennemann about the genesis of the company. This story was been published on Powertrain July, pag. 44. We talked with CJC experts to have a company and products overview.

CJC born from a drop of oil on the nose

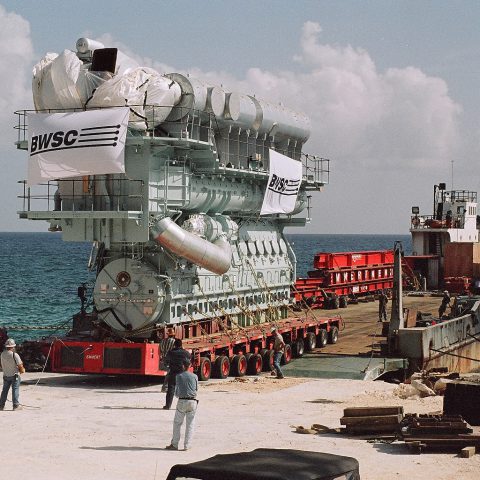

«He was a captain on a ship and it is said that one day a drop of oil fell on his nose. He noticed that it was surprisingly clean, raised his head and noticed that it was drained by a paper flange. He deduced that cellulose was able to clean the oil. The first applications were naval, therefore the filtration of everything that can be hydraulic on board, a hatch, a winch, a crane, an engine. After the war, Jensen met Mr Karberg and Mr Hennemann in Hamburg, and it was on that occasion that they laid the foundations for the company strengthening. Right here is the other factory in the Old Continent. They therefore extended the application of filters to industrial areas, such as transformers, wind turbines, molding presses, wherever there is oil. We said it is a market niche because the company manufactures fine filters, they complete the in-line filters with a more incisive action, filtering the finest particulate and removing water and sludge».

All over the world

The company has branches overseeing strategic locations around the world, including China, USA, Benelux, which also covers France, Spain and Mexico. A production site has existed in Japan since 1965, following a marketing agreement. In China, production has been going on for about ten years. What can you tell us about boating? «Pleasure boating is satisfying because we are also able to filter the fuel, while on large ships, which have a different power supply, we are present for the hydraulic oil of cranes and thrusters, certain winches and lubrication oil for two/four-stroke engines». A short overview of the product. The fuel passes through the fine filtration cartridge, a depth filter that blocks all particles larger than 1 micrometer and in which water droplets agglutinate to form larger drops. In the next stage, these drops coalesce and water collects in the lower part of the separator filter. The Cjc Ptu1 15/25 and Cjc Ptu2 27/27 models allow you to manually drain up to three liters of water: the Ptu1 27/54 and Ptu1 27/108 are equipped with automatic drain thanks to an electromagnetic valve. Made up of 75 percent hollow Linter cellulose structure, the Cjc cartridge removes particles down to 3 micrometers while absorbing dirt. How to correctly size the separator filter? This is all in all simple. To understand how many liters are needed per hour, simply multiply the engine power, expressed in kilowatts, by 0.24 (0.20 in horsepower)».