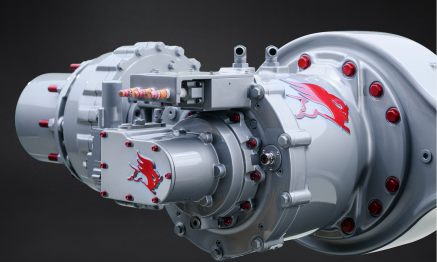

Meritor and electrification. The bull flies on electrified wings

Meritor and electrification, an association of thougts and ideas that accelerates year after year. We will reveal everything later when we publish the full article in Diesel International. On the next post you will also find the PDF. For the time being, you’ll have to be patient and settle for the first lines from T.J. […]

Meritor and electrification, an association of thougts and ideas that accelerates year after year. We will reveal everything later when we publish the full article in Diesel International. On the next post you will also find the PDF. For the time being, you’ll have to be patient and settle for the first lines from T.J. Reed, vice president of Global Electrification.

Meritor and electrification. Can you describe the integration of AxleTech and the interaction with Transpower?

Both companies have been acquired by Meritor in the last year and they both are part of our growth strategy in adjacent markets as well as in advanced clean transportation technologies.

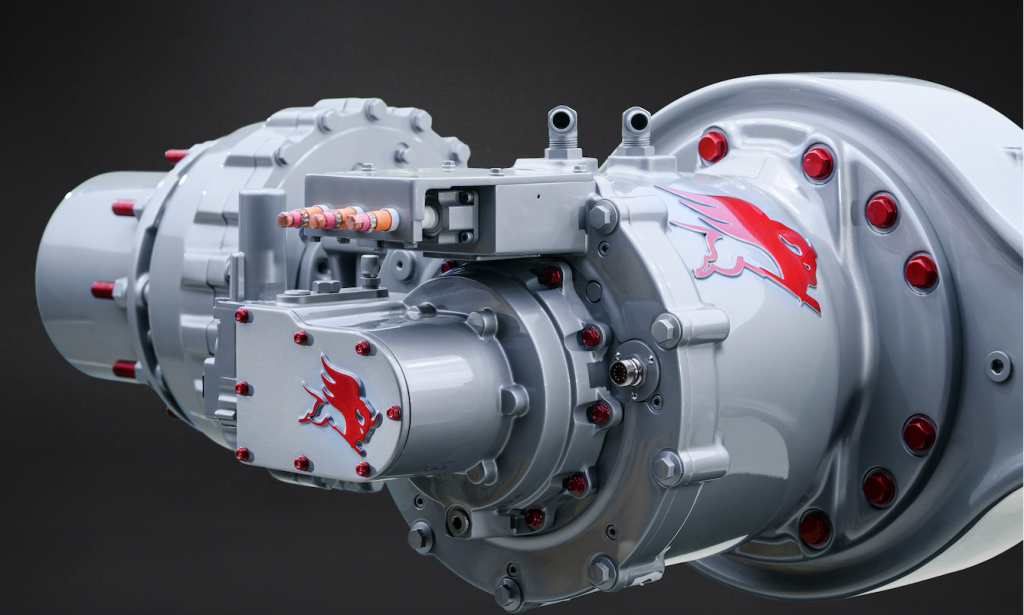

AxleTech brings a comprehensive industry experience and a robust global product portfolio in the defense and off-highway sectors. Our customers now benefit from a deeper product portfolio, manufacturing excellence, and the financial strength to invest for the future. We also acquired their off-highway electrification product portfolio.

The Transpower acquisition enables Meritor to further position the company as a premier supplier of electrification technologies for commercial vehicles with the addition of its product portfolio, Meritor advances its M2022 (its 3 year business plan) priorities through increased investment in next-generation technologies. It also further establishes the value of Meritor’s Blue HorizonTM brand, which represents the company’s emerging platform of advanced technologies centered on electrification.

Both acquisitions have allowed Meritor’s footprint to grow, expanding its reach and differentiating the company from the competition even further. For Europe in particular the integration of the AxleTech facilities means to acquire an important asset to serve both the defense and off-highway business locally and not from overseas.

In the past Meritor has envisioned that 10% of the industrial vehicles will be electrified by 5 years. Do you still see this as an achievable goal?

We expect low-volume production of Meritor’s electric solutions to begin in 2021 and higher volumes to follow as demand for these solutions increases around 2025. As a result of the highly uncertain operating environment due to the coronavirus pandemic we are not in a position to confirm that around 10% of the industrial vehicles will be electrified within the next 5 years.

What are the issues connected to adapting the axles to a powertrain consisting of electric motors and a battery pack compared to the mechanical transmission of a traditional driveline?

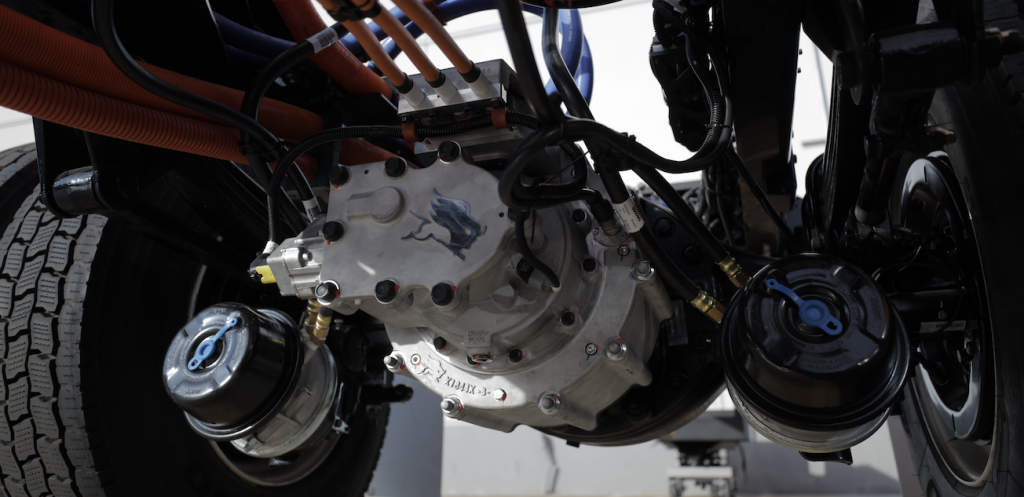

Electrifying commercial vehicle platforms can be done in several ways. The conventional electric vehicle architecture, available today from most OEMs on electric vehicles, where the combustion engine is replaced by an electric motor, does not have a significant impact on the axles and brakes of the vehicle, although Meritor is adopting a series of measures to optimize conventional axle, braking and driveline solutions to better operate in hybrid and electrified systems. One of these measures is the use of the electric motor both for driving as well as braking of the vehicle, only partially possible in diesel vehicles. This makes the duty cycle of the axle more demanding but the duty cycle of the brake less demanding especially in light duty vehicles. For medium / heavy vehicles the brake duty cycle will not really change, until legislation allows us to integrate the regeneration effect in the braking capacity. We are however focusing most of our efforts on being ready to deliver industry-leading electrified drivetrain solutions to our OEM and fleet customers. We do this by developing a best-in-class portfolio of eAxles that offer compact, integrated, high-performance electrified solutions. These technologies are being tested in labs and out on the road in real-world applications gathering data to measure vehicle performance. This eAxle architecture that Meritor proposes as its main solution has a significant impact on the driveline. The electric motor is integrated in the differential carrier while the space between the frame rails is freed and can be used to mount the batteries and accessories or hydrogen tanks in the most protected area of the truck. All obsolete elements such as the motor mounting brackets, gear box and gearbox mounting brackets as well as prop shafts are eliminated from the truck. These eAxles are also designed to benefit from regenerative braking and light-weighting to improve electrified vehicle economics.

COMING SOON… After the summertime