Tovo Gomma, Bosch Rexroth and Hägglunds engines

Tovo Gomma and the advantages of Hägglunds Tovo Gomma is a company operating in the elastomers sector, dealing with the design and production of rubber compounds, vulcanized and expanded sheets. The collaboration between Tovo Gomma and the German multinational began 22 years ago, in the early ’90s, when Tovo decided to integrate the Hägglunds engines, […]

Tovo Gomma and the advantages of Hägglunds

Tovo Gomma is a company operating in the elastomers sector, dealing with the design and production of rubber compounds, vulcanized and expanded sheets.

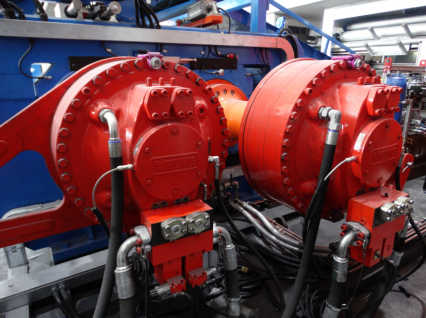

The collaboration between Tovo Gomma and the German multinational began 22 years ago, in the early ’90s, when Tovo decided to integrate the Hägglunds engines, the flagship of the Bosch Rexroth group, into its production machine, the open mixer.

In 1996 they were among the first in Italy to include the innovation of hydraulic actuators in the rubber industry.

The decision comes from the need to have a solution that can adapt to existing machines without excessive costs.

BOSCH REXROTH: CONNECTIVITY FOR HYDRAULICS

Among the advantages offered by the Hägglunds engines, there are the quietness, adaptability, reliability and efficiency in maintenanceand also the emergency stop speed that raises the standards required by the law.

Less than 10 degrees instead of the 57 required by the law. One of the characteristics of the Hägglunds drive is modularity, which allows the initial investment to be preserved.

Andrea Conti of Tovo Gomma said: «We have been working with Bosch Rexroth for over three generations and over the years we have continued to rely on Hägglunds engines not only for the technical qualities of reliability and performance, but also for the availability of advice, able to support us in the different aspects of production.

The purchase of two new machines in 2017 is part of a continuous development in which Bosch Rexroth continues to be a strategic partner of extreme importance».

The future looks “green”

Innovation and sustainability are the cornerstones of Tovo Gomma’s future. Today, the company is working on the development and use of new materials, with a focus on sustainability.

Although the legislation is still rather bland about this topic, the company is already developing new products in a green perspective, using for example vegetable oils that have a much lower environmental impact.

At the same time, Tovo Gomma is working on new technical solutions for a greater recovery of exhausted material and re-processability: to date, in fact, the rubber disposal process is not yet sufficiently ecological.

Davide Borroni, Sales Manager at Bosch Rexroth, said: «The advice offered by Bosch Rexroth has supported Tovo Gomma in maintaining a high level of quality, high efficiency and very limited downtime, thanks to the reliability of the machines and the competence of maintenance technicians.

Since we believe that people are the most important assets of a company, we pay particular attention to their well-being: this is why our systems are particularly silent and guarantee an exceptionally fast machine stop, with only 5-10 degrees of margin».