Innovative materials for transport: an interesting project from Northern Italy

A very interesting study in the field of innovative materials for transport comes from Northern Italy, more precisely from the Veneto region, and concerns the results of the so-called GAP project. The partners of Sinfonet – Innovative Regional Network of Veneto, which is part of the Smart Manufacturing area – have in fact designed and […]

A very interesting study in the field of innovative materials for transport comes from Northern Italy, more precisely from the Veneto region, and concerns the results of the so-called GAP project. The partners of Sinfonet – Innovative Regional Network of Veneto, which is part of the Smart Manufacturing area – have in fact designed and produced more performing cast irons and aluminium alloys that will make the components lighter.

The company Ecor International, in particular, contributed to the study in terms of materials weldability, which has made it possible to evaluate their better and integrated industrial applicability.

The project aimed at finding innovative materials for transport

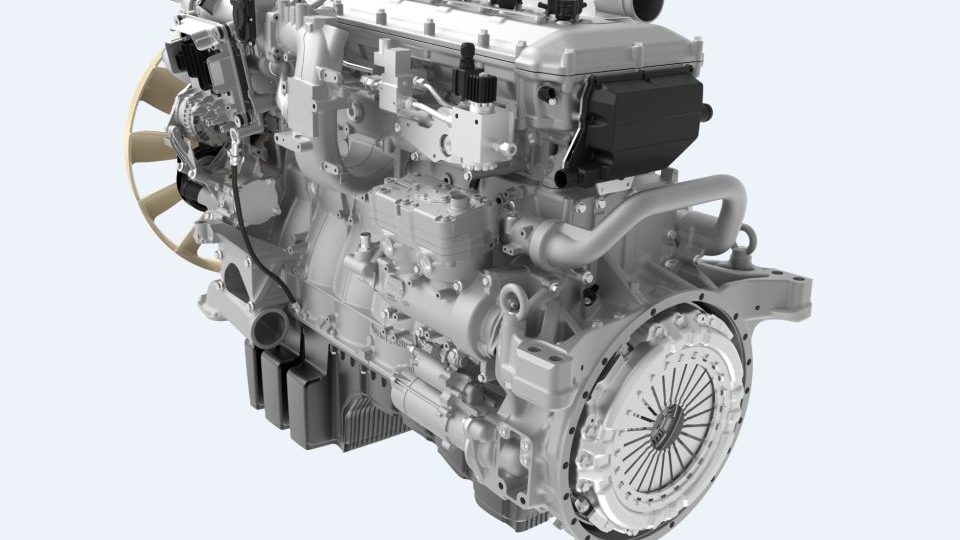

The participants in the project, which took three years of work, developed some innovative materials, namely cast irons and aluminium alloys with improved mechanical properties and resistance to corrosion and wear.

The researchers, for instance, demonstrated that it is possible to produce die-cast components, in aluminium alloy with an optimised composition, with a reduced thickness of up to 30 percent using less material. It has been confirmed that the new material has better mechanical strength and improved process performance.

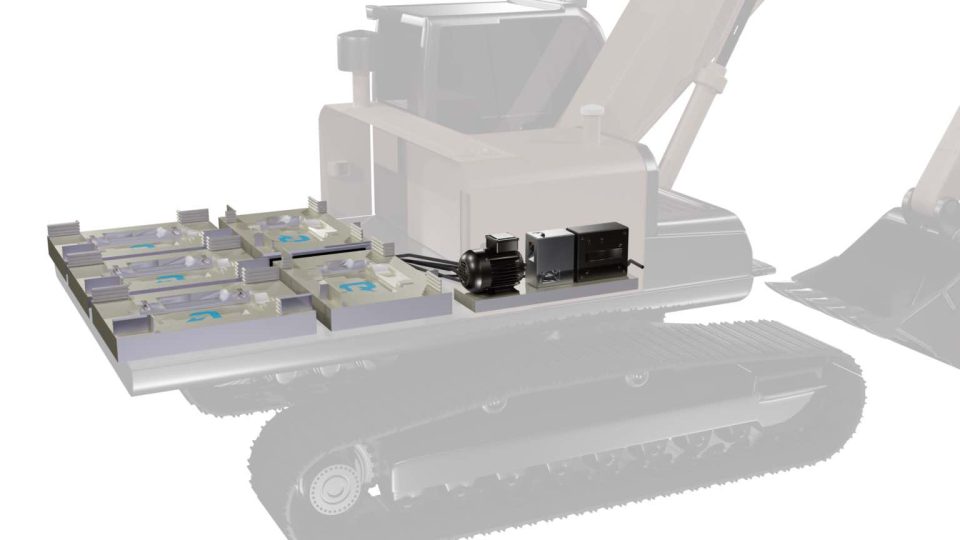

In other words, the components made with innovative cast irons and aluminium alloys will be lighter with significant benefits from an environmental point of view, as this leads to greater efficiency and lower costs, as well as reduced consumption, thanks to a more rational use of energy. The applications can be manifold, with particular benefits in the transport sector (automotive, naval, railway).

The project coordinator’s comment

«We are very satisfied with the results achieved. Now we will be able to make available to designers, processors and end users a series of innovative materials, accompanied by a complete database able to clearly illustrate their potential, limits, advantages, usability in different processes and environments», said Professor Franco Bonollo, coordinator of the project.