Two-stroke engines and efficiency (part 2)

Two-stroke engines have two important advantages over four-stroke engines in terms of efficiency. This article about the link two-stroke engines and efficiency sounds as the natural evolution of the previous research of Serguei Tikhonenkov, MSc. We propose to our readers the second part of the new script by Mr Tikhonenkov. You can read the full article on page 24 of the November issue.

Two-stroke engines have two important advantages over four-stroke engines in terms of efficiency. This article about the link two-stroke engines and efficiency sounds as the natural evolution of the previous research of Serguei Tikhonenkov, MSc. We propose to our readers the second part of the new script by Mr Tikhonenkov. You can read the full article on page 24 of the November issue.

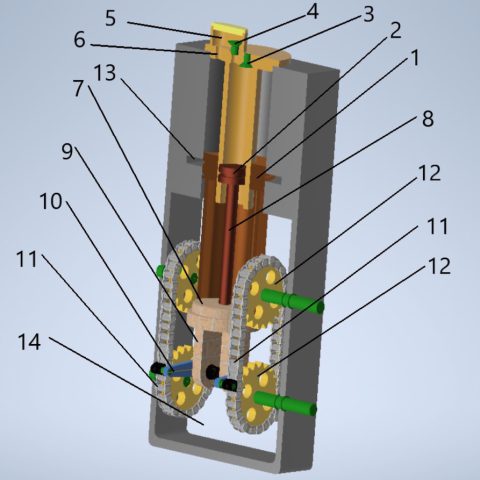

Figure 5 shows a two-stroke engine with the chains. Figure 6 shows four joined two-stroke engines with the chains.

In Figure 5, each unit consists of a main (1) and additional (2) cylinders, an intake valve (3) and a valve (4) connecting the space above the piston of the main and the piston of the additional cylinders, and a common chamber (5). The common chamber and the space above the piston of the main cylinder are connected by a channel (6). On base (7) the piston of the cylinder 1 and a rod (8) of the piston of the cylinder 2 are mounted, and on the lower part of the base there are two struts (9). On each strut there are pivotally mounted the levers (10) which are connected with the chains (11). The chains interact with the sprockets (12). An aperture (13) ensures an exhaust when the piston of the main cylinder reaches its extreme low point. The block crankcase (14) is located in the bottom part.

The engine operates as follows. When the working mixture is ignited above the piston of the main cylinder (1), the valve (4) is closed by the pressure. The pressure makes the piston of the main cylinder and the base move down. At the same time, the rod (8) and the piston of the additional cylinder move downward, while the valve (3) is opened by vacuum and ensures the intake of the combustible mixture. The levers mounted on the struts also move down and pull the chains. At the same time, the chains drive the sprockets, creating the torque. When the piston of the cylinder (1) reaches its extreme low point, the exhaust gases are discharged through openings (13). At this point the sprockets make the levers to complete a 180-degree arc around the sprockets due to interaction with the attached units and pull the chains. After that the base and the pistons of the cylinders 1 and 2 installed on it move upward also due to interaction with the attached units. When moving upward, the mixture entering into the space above piston of the additional cylinder moves through the valve 4 which is opened by pressure, the common chamber and the channel into the space above the piston of the main cylinder. Now the valve (3) is closed by the pressure above the piston of the additional cylinder. Thus, the compressed combustible mixture is created in the space above the piston of the main cylinder. When the mixture is ignited, the cycle repeats.

A join of the four two-stroke engines ensures a sequential execution of the combustion strokes by each engine (Figure 6). One more option of the new conception is the replacement of the crankshaft with gear racks that move linearly and drive the gear wheels creating the torque (Figure 7: two-stroke engine without a crankshaft).

Talking about the differences between the new engine and the traditional one, in the new engine a crankshaft is replaced by the chains and the sprockets. At the TDC, the piston is stationary while the levers run around a 180-degree arc on the sprocket. At this moment, the fuel-air mixture in the space above the main piston ignites. The volume in this case will be kept constant, which will lead to a many-fold increase in pressure and temperature. The moment of the ignition of the fuel-air mixture must be optimized. It will allow us to avoid the destruction of the engine and create a significantly increased pressure above the piston.

Therefore, in the new concept of the engine, the temperature and pressure will be increased because the piston is stationary during the calculated short time at the TDC. It means that the pressure and temperature in the engine as well the power depend on the time of the pistons delay at the TDC. This is a functional relationship.

HP, P, T = f (t); (3)

t – time of the delay

The advantage of the new engine compared with the traditional one is demonstrated in Figure 8. Figures 8a and 8b clearly show that equal amounts of fuel for both engines are used more efficiently in the new one. Also, at the bottom dead center (BDC), the piston is stationary, same as at TDC, while the chains run around a 180-degree arc on sprockets providing a high level of exhaust. As a result, this means that fresh fuel-air mixture will not mix with the remnants of the combusted mixture.

In the proposed engine, the combustion stroke and the intake stroke are performed simultaneously, both strokes being isolated. While the pistons of the main and additional cylinders are moving up, the fresh fuel-air mixture is pumped by the piston of the additional cylinder into the space above the piston of the main cylinder through the valve 4 which is opened by the pressure, the common chamber and the channel. In this case, the intake and the exhaust ports are separated. This means that the new conception of two-stroke engines is significantly more environmentally friendly.

In the proposed engine the lever of tangential force on the drive shaft remains constant along the piston’s entire travel path (Figure 9).

T = P

P=1 -force acting on the piston (conventionally assumed to be equal to 1)

The change in the torque values in the proposed engine is determined only by the change of the pressure in the cylinder. The arithmetic average of the torque in the proposed engine is 1.83 times the arithmetic average of the torque in the traditional engine. Figure 10 shows the variation of the torques in the traditional engine (blue) and the new one (red). We should also note that there are no camshafts and the gas distribution mechanism.

Talking about the conclusions, we can say that the proposed engine ensures significantly reduced fuel consumption as well improved exhaust, fuel combustion and increased durability. The comparison between a four-stroke engine and four joined two-stroke engines has shown improvements in the new engine, which ensures the same fuel efficiency as in four-stroke engines. In four joined two-stroke engines every 180 degrees turn is the combustion stroke, while in traditional four-stroke engines during every 180 degrees turn exhaust, intake, compression and, finally, combustion strokes are performed sequentially. Beside that, the torques of each stroke of four joined two-stroke engines 1.8 time the torque of four-stroke engines.

This is a huge step in the field of ecology. The reduction of fuel consumption will reduce the water, land, and air pollution to the same extent. And, last but not least, the new engines connected to generators will force out nuclear and thermal power stations working on coal.