The EU Competence Center as the pivot of a broad local network: Vulkan Turkey and Vulkan Italy work together

The EU mounts Competence Center created by Vulkan and located in Italy was born to coordinate the work of the Company’s local branches all over Europe by sharing technical know-how and experience. We asked Kagan Hasircoglu, General Manager at Vulkan Turkey, and Fabio Santoro, Sales Manager and Vulkan resilient mounts Product Manager at Vulkan Italia, […]

The EU mounts Competence Center created by Vulkan and located in Italy was born to coordinate the work of the Company’s local branches all over Europe by sharing technical know-how and experience. We asked Kagan Hasircoglu, General Manager at Vulkan Turkey, and Fabio Santoro, Sales Manager and Vulkan resilient mounts Product Manager at Vulkan Italia, to tell us from the beginning to the current stage the story of a concrete refit project with a vessel – namely, My Elements – made by a primary Turkish exclusive yacht shipyard, Yachtley.

How did Vulkan Turkey get in contact with Yachtley shipyard? And which were the main requirements expressed by the customer?

Kagan Hasircoglu (HK): We work with several shipyards in Turkey. Yachtley is a very important one, as they are making big investments in the Kocaeli area in particular. When they started building mega yachts, about 80 meters long, we began to work with them.

They needed some improvements about the vibroacoustic management and they were looking for a partner. In this particular project, the direct contact dates back to Monaco Yachtshow, in 2019.

The solution adopted

Which was the solution adopted eventually (products chosen, for example), and why?

HK: Yachtley originally used semi-rigid resilient mounts mounted on the reduction gear and conical-mounts on the main engine provided by a previous supplier, while they did not use any tailshaft coupling. The topic we discussed with them was to reduce vibrations especially on the upper deck.

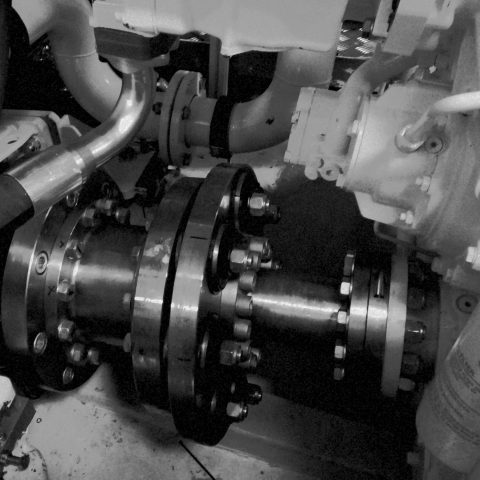

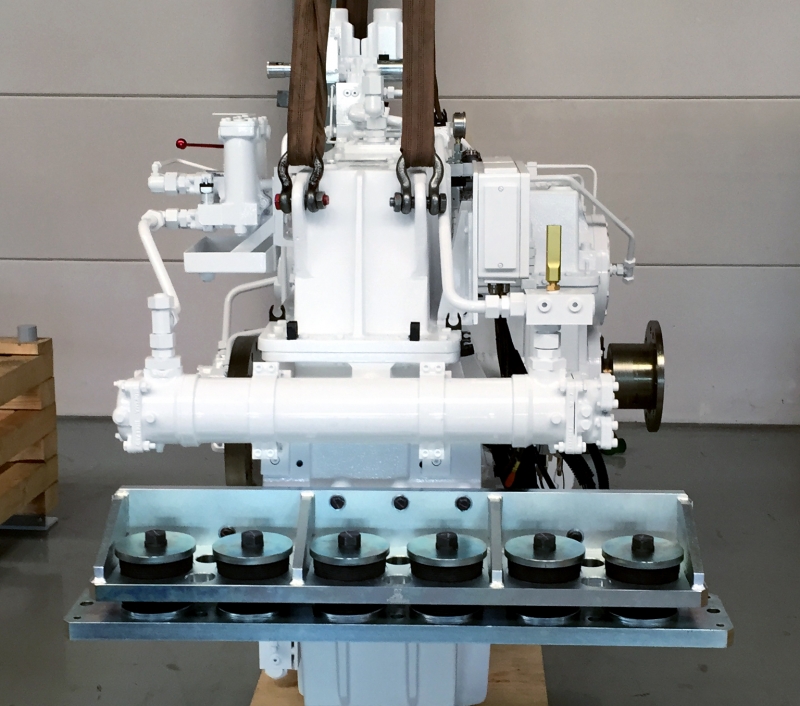

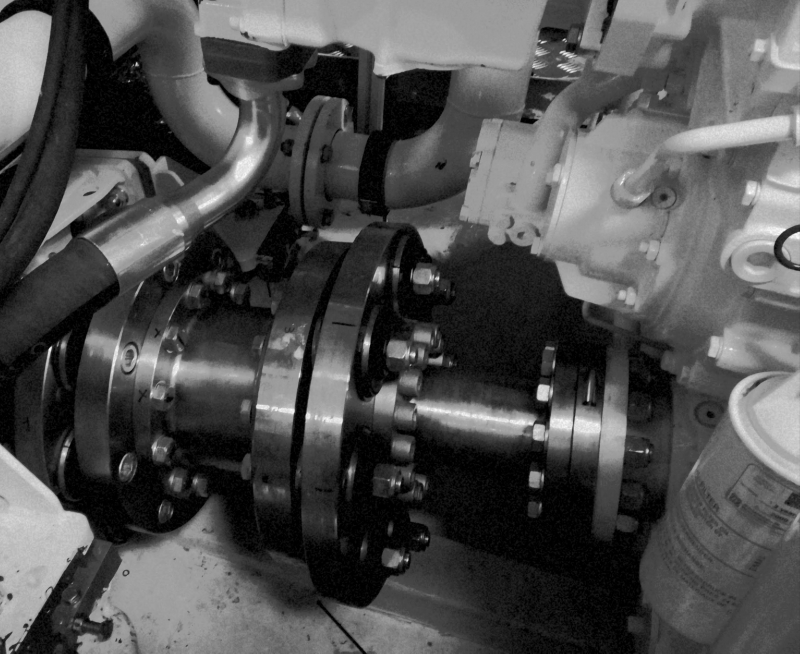

We discussed with the experts from the Competence Center at Vulkan Italia to find the best solution in order to improve the vessel’s vibroacoustic conditions: the products chosen were the softer CV 2000 gear mounts for the gearbox and the Propflex T160-14-D coupling on the shaft line to eliminate the vibrations and acoustic issues.

Fabio Santoro (FS): The first target was to absorb the thrust load from the propeller to the gearbox through the Propflex T. In order to do this, we put a tail shaft coupling with a built-in thrust bearing. By removing the thrust load from the gearbox, we have the possibility to use more flexible and softer mounts on the gearbox, choosing the CV 2000 mount. By using a softer mount, we got significant noise and vibrations reduction to get the requested vibroacoustic comfort from the customer

Which are the main issues and criticalities when dealing with a refit project on a megayacht like the one we are talking about?

HK: Working with megayachts is very challenging indeed. Our approach is quite realistic. First, we visit all of our customers on board, we listen to them and find how we can optimize the system through troubleshooting and dedicated noise and vibrations measurement campaign agreed together with the Competence Center. After a deep data analysis, the decision about how to improve the system is taken together.

FS: Let me add that a refit is something very different from a new project; it means you have to face some constraints on board. It is a criticality indeed, but somehow an advantage for us, because we can rely on quite a relevant know-how coming from our experience every time we take care of a different project.

How did Vulkan manage the whole project? Could you please tell us something more about the relationship between Vulkan Turkey and the Competence Center in Italy?

FS: As for the Competence Center, we take care of both refitting and first equipment applications. In this particular case, we have adapted to the Yachtley project a solution previously proven with good results in a first equipment project in Italy. It was a customized solution based on some standard products.

The collaboration with Vulkan Turkey was extremely good and it was important to have all the dataset to analyze this particular case, check the engineering, calculations, layout and existing space constraints. At the same time, we are able to study and develop new solutions, based on our solid experience of decades.

The same CC approach is followed worldwide by the other mounts in USA, China working with the Vulkan subsidiaries in their own world areas.

The benefits of the Competence Center promoted by Vulkan

How does the Competence Center actually work? Which are its main benefits, in your opinion?

FS: We provide technical sales and logistic support, so prices, drawings, analysis, design and supply of the components. Our target is to make the local subsidiaries able to provide a quick response to the customers: the timing of our actions is really important in order to stay close to the customers and provide a very fast answer.

In addition, I can say that every part of the Vulkan family plays its own role. Coming back to the Yachtley case, Vulkan Turkey had a direct relationship with the customer, a good knowledge of the market and technical know-how. the Competence Center has got a deep knowledge on the products, customized solutions and our overall view experience. Vulkan Germany assisted us especially on the couplings: the selection, TVC analysis and so on. It is a sort of puzzle in which each side has its own role to get the final and best result for the Customer.

Vulkan has re-organized its global structure in the last years in order to be perceived more and more as a solutions supplier instead of a product supplier. What kind of feedback are you experiencing from the market about such an approach? Are customers truly aware of this role played by Vulkan?

HK: I’d like to talk about the example coming from Turkey. A few years ago, we started acting as a solutions provider with a tugboat project, where we offered our customer some solutions about couplings, resilient mounts, composite shafts, all the analysis and calculations and so on.

Today, when customers work with us, they know they can get a naked propulsion unit, and Vulkan can fill the necessary additional equipment with its own product catalogue, supporting them in the best vibroacoustic choice. Moreover, the glocal assistance provided by Vulkan is another big advantage to them.