Nino De Giglio reveals Kohler’s hybrid K-Hem

K-HEM. Kohler speaks hybrid language Under the lights of Eima 2018, Kohler wanted to confirm its protagonist role in the agricultural machinery sector. Can you tell us what are the news you brought to Bologna? Eima visitors had the possibility to observe all our KDI engines range at Kohler’s stand, characterized by compactness, high performances, […]

K-HEM. Kohler speaks hybrid language

Under the lights of Eima 2018, Kohler wanted to confirm its protagonist role in the agricultural machinery sector. Can you tell us what are the news you brought to Bologna?

Eima visitors had the possibility to observe all our KDI engines range at Kohler’s stand, characterized by compactness, high performances, low consumption, easy installation and optimized solutions for emissions control. KDI engines are equipped with Kohler Flex, the family of filtering solutions for emission control that Kohler developed to allow for each configuration of KDI engines to properly comply with all the different standards on this matter, all over the world.

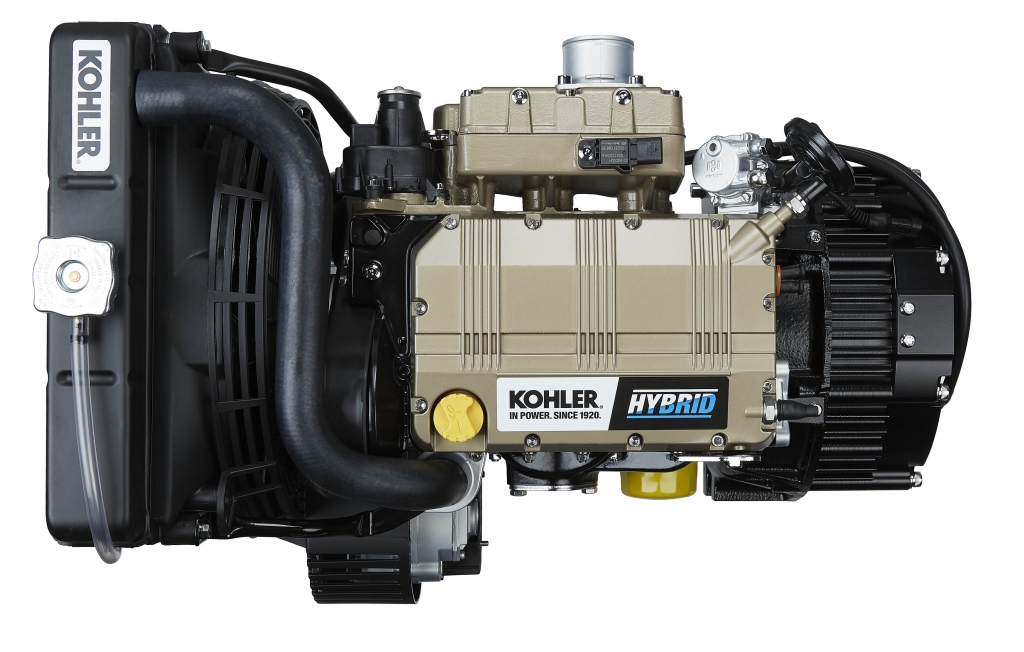

The new K-Hem unit clearly took over the scene at Kohler’s stand, can you tell us its main characteristics?

Kohler presents K-HEM (Kohler Hybrid Energy Module), the hybrid unit for electric and mechanical combined power generation. K-HEM is the power generation unit given by the combination of the KDW1003, 18 kW, diesel engine, complying with the Stage V standard and without DPF and the 48 Volt electric engine that generates 15 kW at max output and 9 kW as regular output. So, the unit has the ability to provide over 30 kW of power without using any after-treatment system.

What kind of applications are best suited for the K-HEM unit? On which agricultural machines can we see it installed on? How long will it take for a real entry into the field?

The characteristics of K-Hem hybrid unit are thought to be applied to all those applications that operate under the condition of discontinuous work cycles that require power peaks (welders, lawnmowers, tractors with accessories for agriculture, etc.) and to the machines that operate with constant work cycles with low load levels that don’t allow to reach the required temperatures to activate the passive regeneration within the particulate filter (forklifts, etc.). K-HEM will be installed, in the near future, to different agricultural and industrial applications.

What does it mean, for a company like Kohler, to explore new power generation sources?

There are already different energy sources on the market and the Kohler’s goal is not to create more competition in the research of alternative energy sources, but the idea is to explore and analyze these sources to integrate them and exploit their already existing potential. This decision follows perfectly the vision of the company: to always be at the forefront in technology and innovation to offer the best solutions available on the market.

FOCS. For the moment…

Are you developing more projects concerning the fields of hybrid technology and alternatives to the diesel for power generation?

As of today, allthe FOCS family of engines can be applied to the hybrid technology. The next step in development is the creation of a unit that allows to select the engine to use based on the type of cycles of work; a module that allows the final user to switch from thermal to electric with a simpple click on the master control unit.

At the Intermat 2018 press conference, you said that the future is still going to be diesel. How long do you think the diesel will keep its dominant position in the agricultural sector? Why is it so difficult to implement ‘full-electric’ systems, or also other alternatives, like LNG, that seem to spread quickly in other other sectors, including heavy transport?

The market requires always more productivity for agricultural and industrial sectors, with high performances and low management costs. Right now, only the internal combustion engines are able to satisfy such requests, while also fully respecting any standard in terms of emissions. Diesel engines from the off-road sector saw an extraordinary technological development in the last decades and they will continue to progress in the next future to guarantee the respect of the law and the performances requested by the market. Our mission is to develop and provide to our clients only solutions that we value as at the highest levels of available technology and innovation.