Vulkan and the efforts for noise and vibrations reduction on board

Gianpiero Repetti, Managing Director at Vulkan Italia, explained us how the company is facing issues such as noise and vibrations on board. Talking in particular about some refit interventions addressed to existing boats. Interventions that arise from what needs? And what are the main causes of noise or vibration on the boats? We can distinguish […]

Gianpiero Repetti, Managing Director at Vulkan Italia, explained us how the company is facing issues such as noise and vibrations on board. Talking in particular about some refit interventions addressed to existing boats.

Interventions that arise from what needs? And what are the main causes of noise or vibration on the boats?

We can distinguish two typical needs: that of a ship owner who, through his trusted broker, decides to put his ‘old boat’ on the market to bring it up to a current standard in terms of vibro-acoustic comfort, and therefore to increase its market value. The second one is that of a ship owner who feels a discomfort of some kind: he has, in other words, the need to improve his experience on board and that of his guests, friends or customers.

VULKAN AND THE VIBRO-ACOUSTIC COMFORT

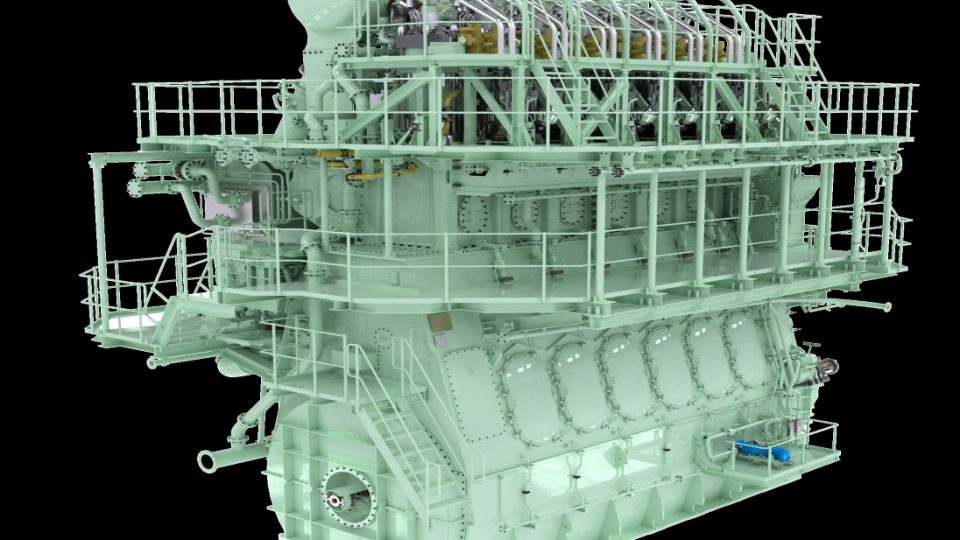

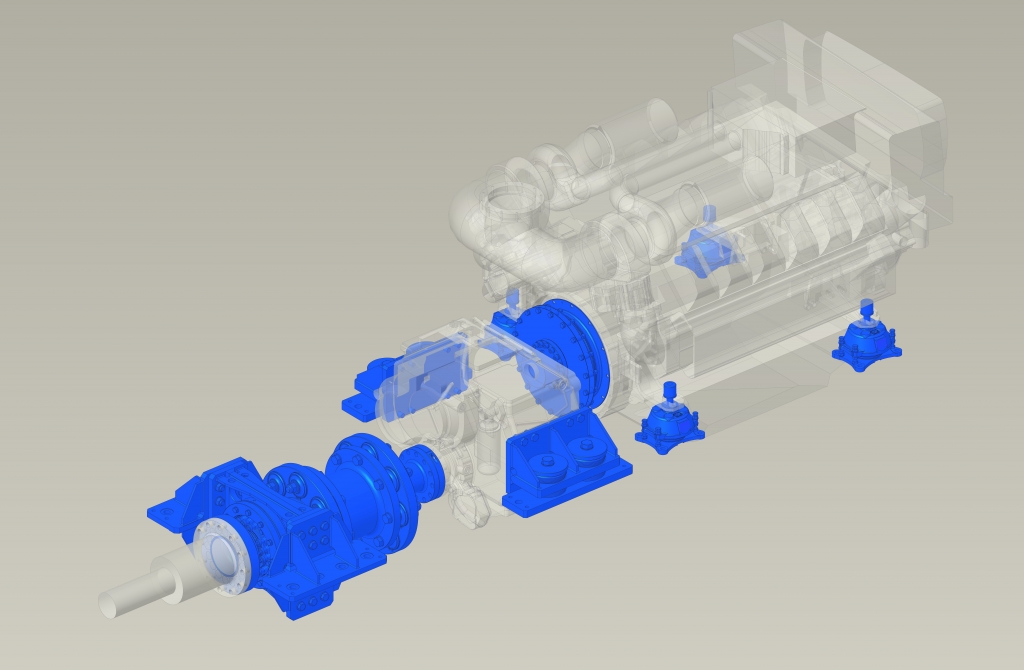

The intervention takes into account the effects that noise causes on the receiver, to identify the cause, or rather the source. Naturally, the propulsion system is among the main suspects; however, there may also be other causes: malfunctioning hydraulic circuits, random phenomena created by liquids in circulation or caused by external events, and so on.

What is the approach of Vulkan to refit?

The basic objective remains to improve comfort on board. First of all, we try to understand what the current state of the boat under review is and what points can be improved. We identify disturbances, by measuring vibrations in terms of dominant frequencies, warned by the receiver and we go back to the source of the noise.

By definition, this is transmitted by structural means and by air: by structural means, at lower frequencies or by air, at higher frequencies up to 20 kHz, and then we talk about ultrasounds, therefore not audible to the human ear.

HOW TO CREATE A NEW ANTI-VIBRATION SYSTEM, ACCORDING TO PATRINI

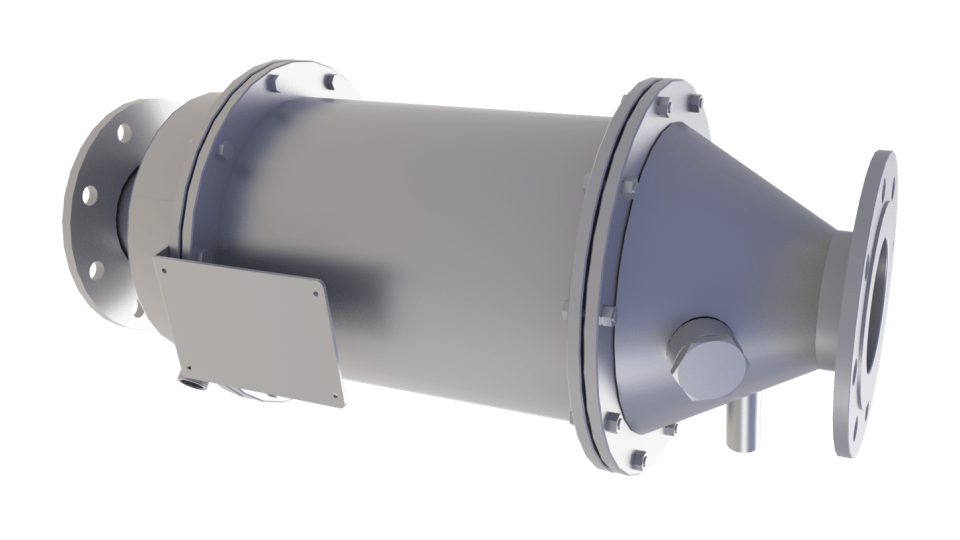

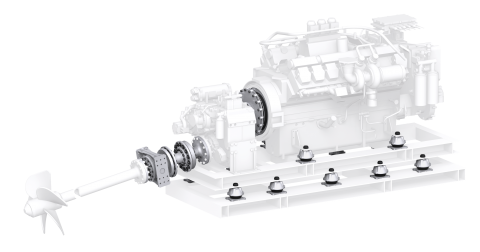

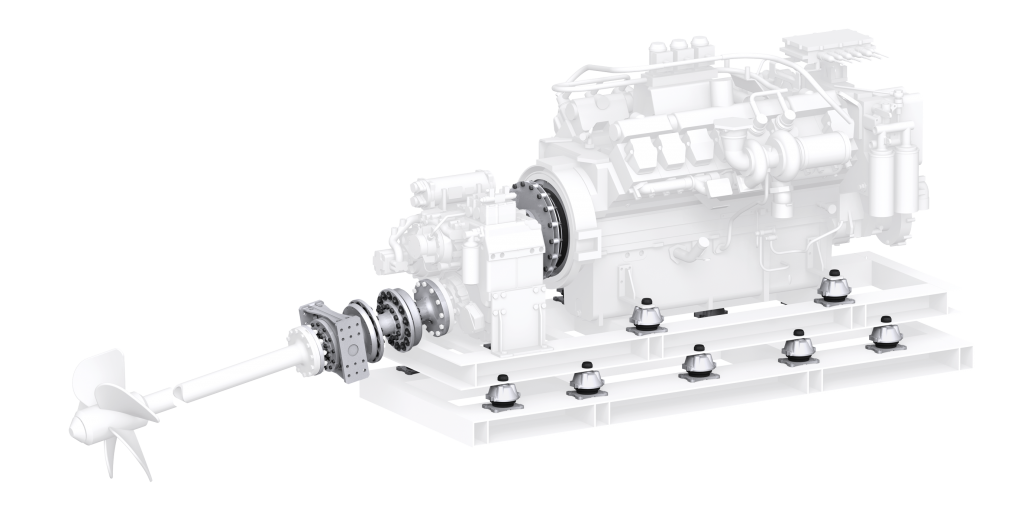

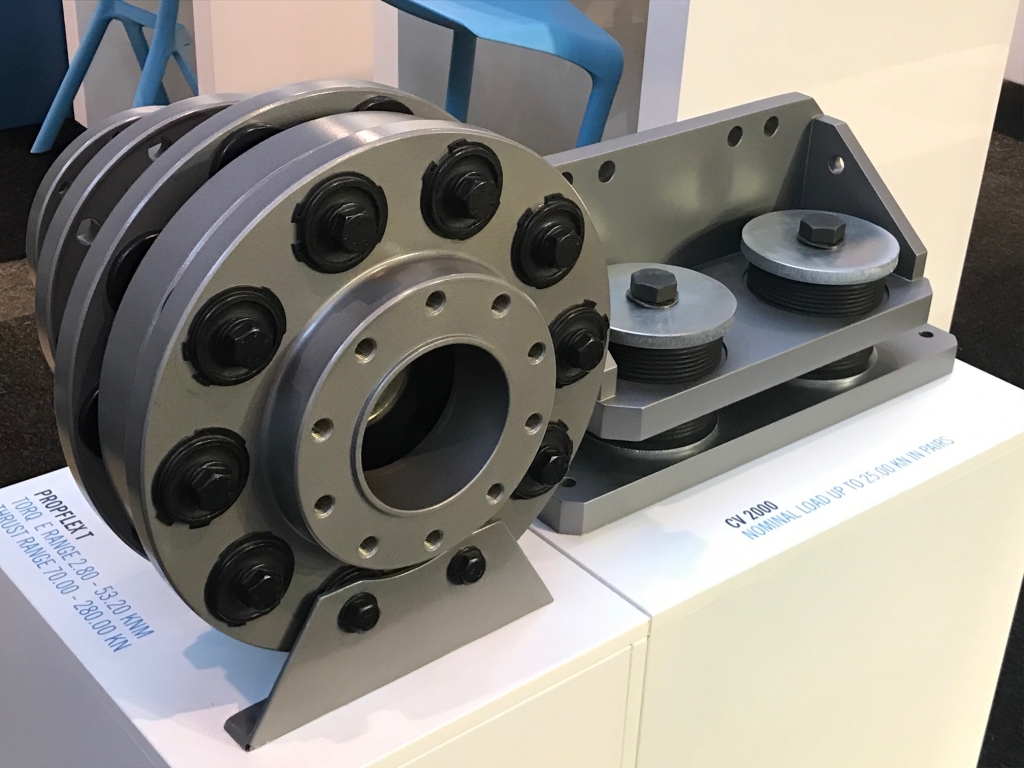

Once this first examination is complete, we are able to intervene first of all on the structural way, a means that brings the vibration to any point, even remote, of the boat. We therefore suggest the necessary interventions to reduce the propagation of vibrations from the source, applying suitable cutting and damping systems such as, for example, supports and elastic joints.

In other words, we intervene to isolate, as far as possible, the noise source from the receivers, by means of suitable systems.

A practical example?

We start with a vibration felt on the bridge, of which we identify the dominant frequencies with the measurement. Once we have identified the frequency, we go back to the cause, considering the relationship that exists between the rotation speed of the source (the propulsion engine, for example) and the frequency detected on the deck.

Speaking of numbers, for example, if the discomfort felt at low frequency has the frequency of rotation of the axis, we could say that we are facing a misalignment of the axis itself; if it is a multiple of the engine speed, it could be caused by combustion. In this case, we might provide a suitable isolation with anti-vibration mounts.