CXO300 by Cox Powertrain, when Diesel flexes the muscles…outboard

The mass production of the COX300 is a new lifeblood for the Diesel cycle for this unusual outboard application. We talked a lot about Cimco Marine’s OXE. Here we publish the communication from the UK instead. CXO300 by Cox Powertrain. From UK Cox Powertrain is pleased to announce the start of production of the CXO300, […]

The mass production of the COX300 is a new lifeblood for the Diesel cycle for this unusual outboard application. We talked a lot about Cimco Marine’s OXE. Here we publish the communication from the UK instead.

CXO300 by Cox Powertrain. From UK

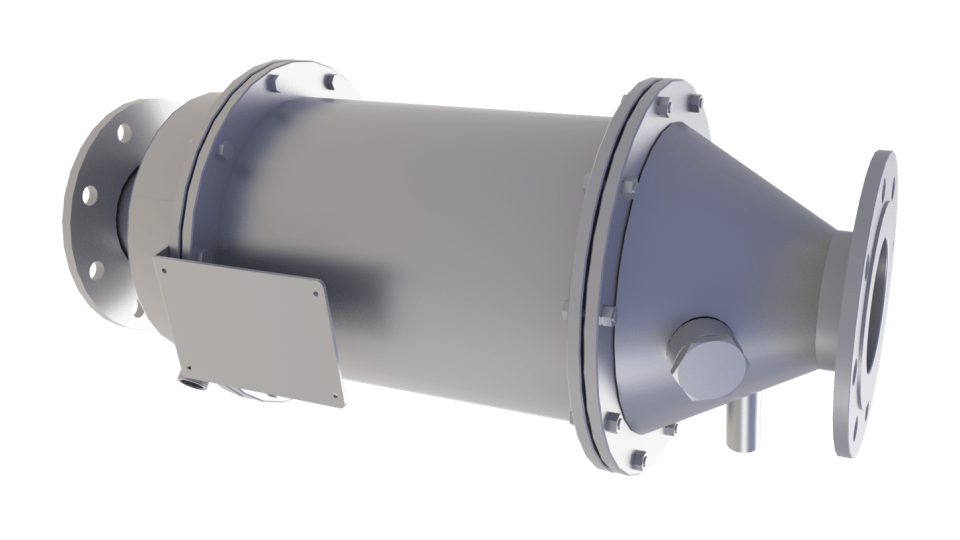

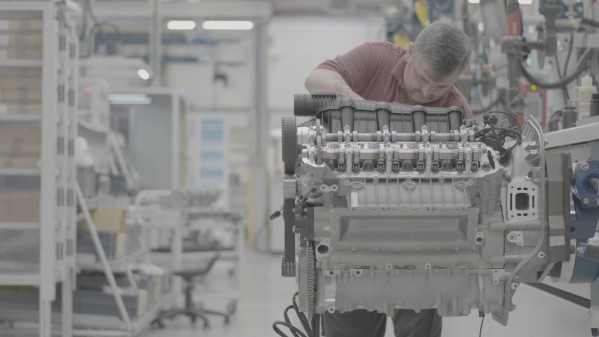

Cox Powertrain is pleased to announce the start of production of the CXO300, its purpose-designed 300hp diesel outboard engine. After several years of intensive development and testing this represents a major milestone for Cox as well as a defining moment for the marine industry. This UK-designed and manufactured high-technology product will be sold to the global market, boosting UK exports. Production will commence in Cox Powertrain’s headquarters and advanced assembly and test facilities in Shoreham, West Sussex UK. The sophisticated assembly plant boasts a turnkey Production System developed by QM Systems Ltd, a leading manufacturer of state-of-the-art manufacturing and test systems across all industries. Significant investment has been made to introduce a manufacturing plant capable of producing up to one engine per hour. The production line ‘no faults forward’ design removes the possibility of assembly error, ensuring every outboard meets Cox’s requirement for the highest standards of quality. These are verified on a suite of purpose-built test cells which put every engine through its paces before shipping to the customer. Cox has applied industry best practice at all stages of the design, manufacture and test process to ensure global success of the engine and the brand. Tim Routsis, Cox’s CEO said: «This is a milestone we have been working towards for quite some time with a relentless focus on building a no-compromises business. I am enormously proud of the CXO300 and the terrific team who have worked tirelessly to make it a reality. We owe a debt of gratitude to the supply chain who have found ways to keep parts flowing to us despite Covid-19, and also to our global distributors who have remained loyal throughout. I am delighted that we can now repay that commitment by supplying this ground-breaking marine engine in volume, together with the support levels expected of a premium product.» Throughout its development the engine generated substantial interest across all applications of the marine industry, a contributing factor for the company when raising the £92m ($115m) of private investment to date required to reach this point. This is a powerful testament to the credibility of the engine concept and the high level of expertise behind its development. Cox’s Chairman, Charles Good commented: «This brings to fruition a long-held ambition of mine to create a UK based business to design and manufacture diesel outboard engines to meet a major unfulfilled need in the global marine propulsion market.»