On the verge of decarbonization. MAN B&W ME-GA engine gets plenty of orders

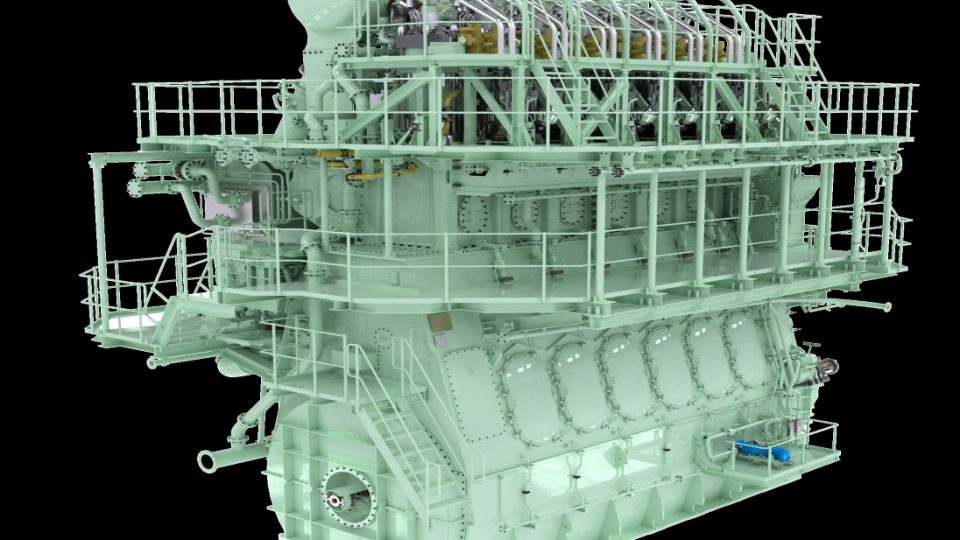

MAN Energy Solutions' B&W ME-GA dual-fuel engine has landed 40 orders since its market unveiling in March 2021. The company attributes the order surge to the market’s demand for the latest generation of Otto-cycle, two-stroke engines and the low levels of methane slip it can unlock.

MAN Energy Solutions’ B&W ME-GA dual-fuel engine has landed 40 orders since its market unveiling in March 2021. The company attributes the order surge to the market’s demand for the latest generation of Otto-cycle, two-stroke engines and the low levels of methane slip it can unlock.

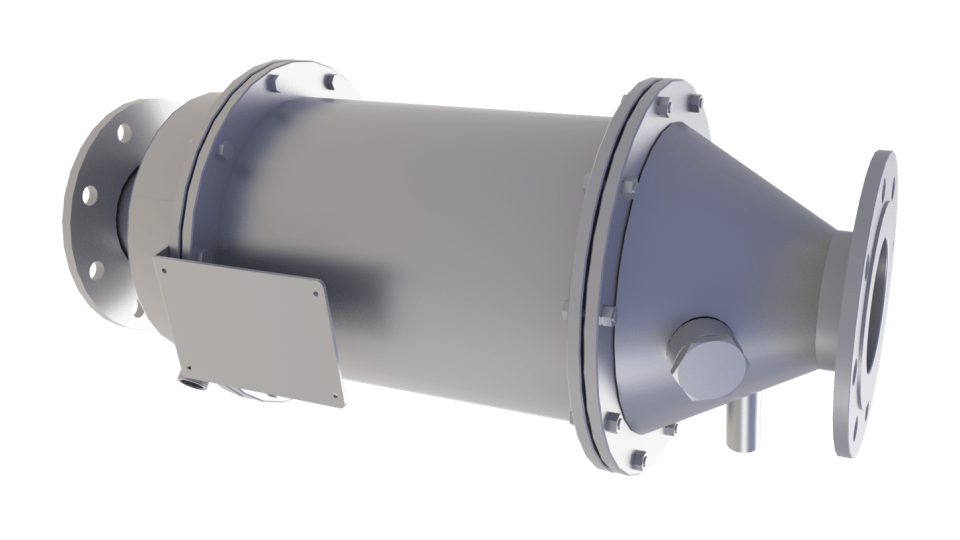

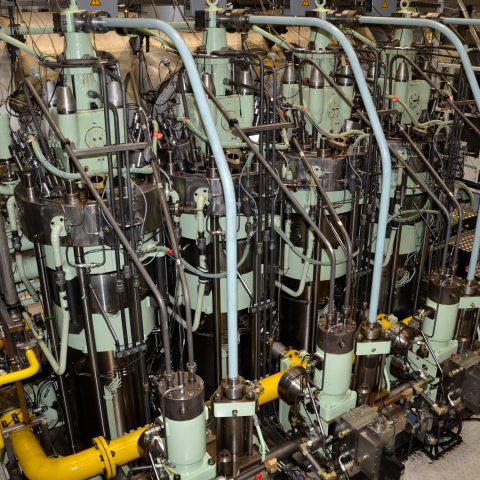

As its pre-mixed combustion results in low NOx emissions, the ME-GA engine is inherently Tier II and Tier III compliant in gas-operation mode. EGR enables the significant reduction of methane slip, while simultaneously improving fuel efficiency in both gas and fuel-oil operation. Ultimately, EGR actively reduces emissions and improves efficiency in both Tier II and Tier III.

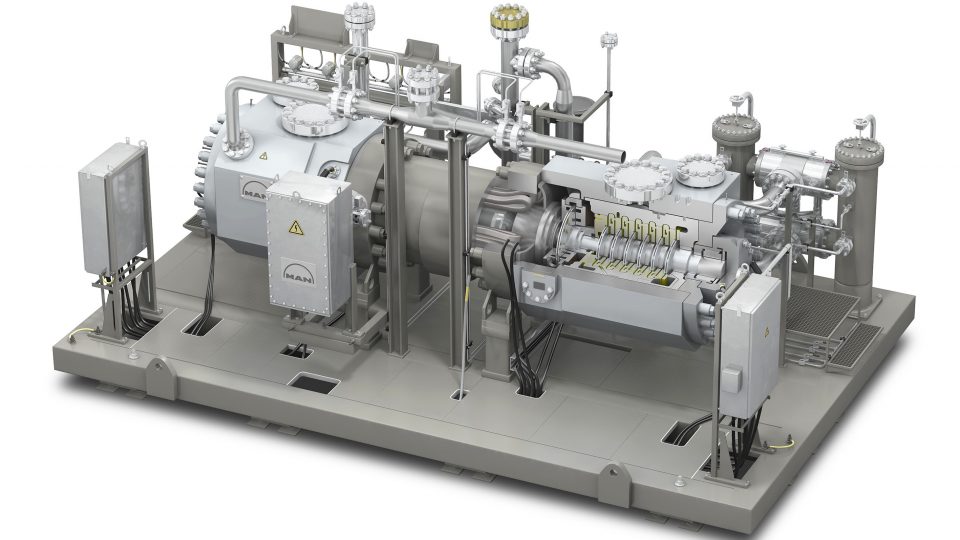

MAN B&W ME-GA engine

Bjarne Foldager, Senior Vice President and Head of Two-Stroke Business, MAN Energy Solutions, said: «We had high expectations for the ME-GA upon its launch as we recognised a strong desire – primarily from the LNG carrier market – for an alternative to our successful ME-GI engine. Judging alone by the fact that ME-GA has won references from all three major shipyards in Korea, these expectations have been met and even exceeded».

«The ME-GA engine is just MAN Energy Solutions’ latest initiative to decarbonise shipping and further the maritime energy transition to sustainable fuels. Our dual-fuel engines continue to act as standard bearers for environmentally-friendly, reliable propulsion-technology with their seamless switching between fuels. Ultimately, we expect the ME-GA to become standard among LNG carriers», he added.

Potrebbe interessarti

MAN ES to take part in research project on greener energy storage solution

Hyundai Heavy Industries like ME-GA engines for LNG carriers

Among the relevant order received for the aforementioned engine range is the one requested by HHI-EMD (Hyundai Heavy Industries‘ Engine Machinery Division). We’re talking about 12 × low-pressure, dual-fuel engines chosen for series of LNG carriers. More into details, HHI-EMD has ordered 2 × 5G70ME-GA10.5 engines for each of 6 × 174,000-m3 LNG carriers for shipowners KLC (2 vessels), PANOcean (2), Knutsen (1), and JP Morgan (1). Hyundai’s Shipbuilding Division (HHI-SBD) will construct the vessels in Korea, which will be chartered by Shell Tankers (Singapore) Private Limited on delivery to the shipowners.

Delivery of the first engine is scheduled for August 2022, with the final unit arriving during the following year. MAN Energy Solutions reports that each of the engines will feature its proprietary EGR (Exhaust Gas Recirculation) system for emissions reduction.