MAN Energy Solutions: dual-fuel retrofits towards decarbonization in the marine sector

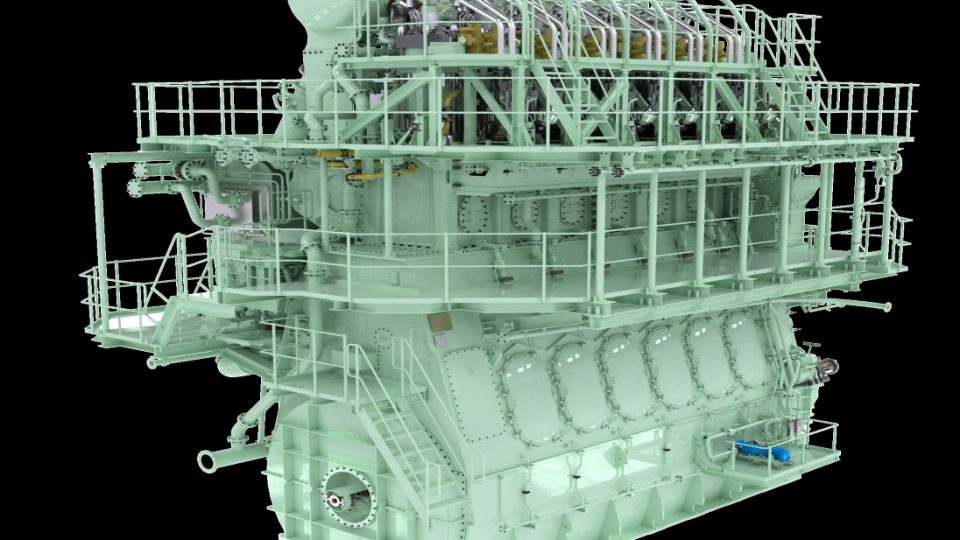

In light of the emerging trend for decarbonisation within the marine sector, MAN Energy Solutions notes that the modular design of the conventionally fuelled, low-speed ME-C engine portfolio lends itself to extensive retrofit options in regard to alternative green fuels, and that such retrofits already have a proven track record.

In light of the emerging trend for decarbonisation within the marine sector, MAN Energy Solutions notes that the modular design of the conventionally fuelled, low-speed ME-C engine portfolio lends itself to extensive retrofit options in regard to alternative green fuels, and that such retrofits already have a proven track record.

Thomas S. Hansen, Head of Promotion and Customer Support, MAN Energy Solutions, said: “At MAN Energy Solutions, we design and service many of the global fleet’s low-speed engines, in effect contributing to worldwide CO2 emissions. As a result, we feel a great responsibility in pursuing decarbonisation and thus we are pleased that many sources predict that more than half of all newbuildings will specify dual-fuel engines after 2025. Since ships have an average lifetime of around 25 years, the retrofit of vessels will be necessary in order for the industry to decarbonise.”

Indeed, as the demand for engines and ships designated ‘future-fuel ready’ increases, MAN Energy Solutions – through its after-sales division, MAN PrimeServ – has a proven, unique track-record with such conversions and has already completed 16 such projects with the first dating back to 2015. Customers can benefit from the fact that all of MAN Energy Solutions’ conventionally-fueled ME-C low-speed engines ordered today can be converted to alternative fuels at a later time when the future-fuel landscape is more clear.

MAN Energy Solutions: ready for green fuels

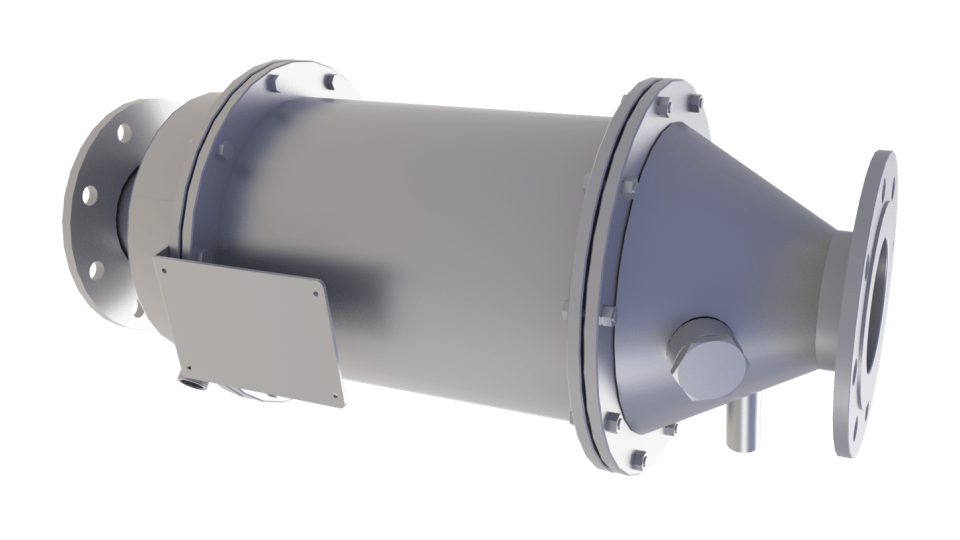

Klaus Rasmussen, Head of Projects and PVU Sales, MAN PrimeServ, said: “A massive number of vessels in the current, ocean-going fleet have the potential for conversion, and our broad and continiously expanding portfolio of dual-fuel engines offers extensive options when it comes to retrofitting. The huge market potential within, for example, S/G50-, G95- and G80-bores for conversion to methanol running as ME-LGIM units is especially notable.”

MAN Energy Solutions’ engine designs currently drive some 22,000 vessels globally, of which 3,500 are fully electronically controlled and with the potential for conversion to operate on alternative, green fuels. It has further evaluated that approximately 2,300 or so of these vessels are appropriate candidates for retrofitting, resulting in savings as much as 86 million tons CO2 emissions annually when fueled by carbon-neutral fuels.

In December 2020, Oslo-listed BW LPG – the world’s leading owner and operator of LPG vessels – announced that it would retrofit a further three MAN B&W 6G60ME-C9.2 type engines to MAN B&W 6G60ME-C9.5-LGIP dual-fuel types, capable of operating on fuel oil and LPG. This brought the number of such conversions announced by the company to 15 with all to be carried out by MAN PrimeServ.