MAN Energy Solutions: ME-GI engines for CLdN vessels

MAN Energy Solutions has won the order for 4 ME-GI engines in connection with the construction of two hybrid RoRo vessels for CLdN, the Luxembourg-based shipping group. Both 234-metre vessels are scheduled for delivery in the first half of 2025.

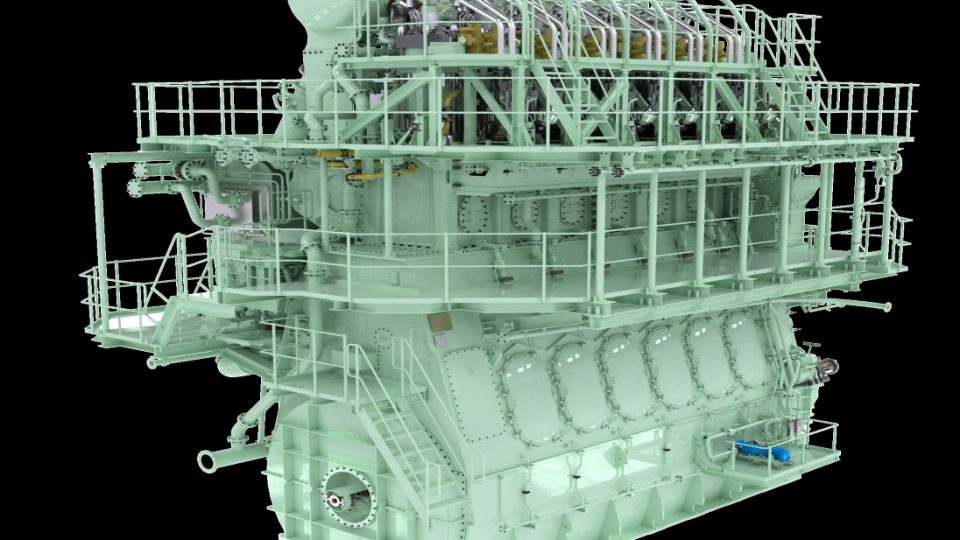

MAN Energy Solutions has won the order for 4 × dual-fuel MAN B&W 6S60ME-GI engines in connection with the construction of two hybrid, 8,000 lane-metre, RoRo vessels for CLdN, the Luxembourg-based shipping group. Both 234-metre vessels are scheduled for delivery in the first half of 2025.

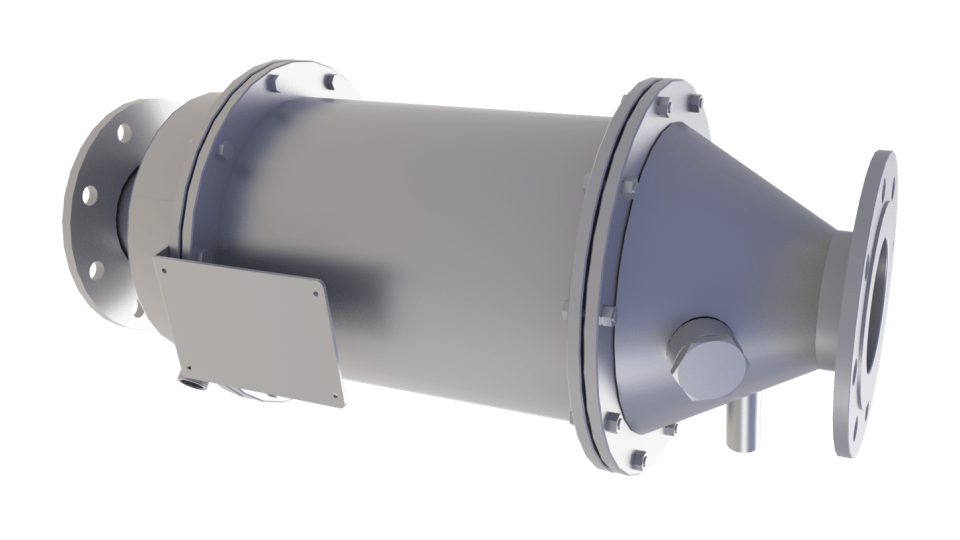

The two newbuildings will have a hybrid propulsion system with each featuring 2 × ME-GI engines (2 × 11 MW) along with MAN Energy Solutions’ propietary EGR (Exhaust Gas Recirculation) emissions system.

Both RoRo vessels will also be supplied with 2 × 6 MW electric propulsion motors that will enable the ships to maintain a service speed of 16-17 knots in full-electric mode. Additionally, each RoRo will have 2 × 678 kWh batteries and while the vessels will still have emissions during in/out port manoeuvering, shore connection is provided and will offer zero emissions in port. Furthermore, each engine will be equipped with a PTO, while the vessels’ respective shafts will come equipped with a clutch ready to deliver a PTH of 6 MW.

CLdN reports that, compared with its largest vessels currently in service, the new ships – the largest investment in its history – will further reduce carbon intensity by 40% while being NOx Tier III-compliant.

Thomas S. Hansen, Head of Promotion and Customer Support, MAN Energy Solutions, said: “This order features a technologically advanced propulsion-train and having the ME-GI engines at its heart makes it a truly future-proof solution. ME-GI engines offer the industry’s lowest CO2 and methane-slip emissions for LNG-fuelled vessels. The engines’ green credentials also boost CLdN’s current status as among the greenest RoRo operators in the world, while pushing its ambition to further reduce its own carbon footprint.”

MAN ES: the ME-GI engine

MAN Energy Solutions ME-GI (-Gas Injection) engine has set a new industrial standard for two-stroke propulsion engines aboard – among others – RoRo vessels, PCTCs, container vessels, bulk carriers, tankers and LNG carriers. The ME-GI engine provides ship owners, charterers and operators with a peerless solution within environmentally friendly and high-efficiency, two-stroke technology but without the prominent methane-slip emissions that are characteristic of competing engines.The Diesel principle not only provides the ME-GI engine with high operational stability and efficiency, but also ensures 100% reliable operation during load changes on gas with just normal additions of pilot-oil amounts. Furthermore, the ME-GI operational principles features a seamless change-over between gas operation and diesel operation. The ME-GI engine is the most environmentally friendly technology available within the LNG-fueled, two-stroke engine segment.