MAN Engines: the first dual fuel hydrogen engines in use on a work boat

One month ago, MAN Engines put its first two dual fuel hydrogen-powered engines for work boats into serial operation. These comprise two twelve-cylinder diesel engines of type MAN D2862 LE448, each with an output of 749 kW (1019 hp) at 2100 rpm.

On 10th May 2022, MAN Engines put its first two dual fuel hydrogen-powered engines for work boats into serial operation. These comprise two twelve-cylinder diesel engines of type MAN D2862 LE448, each with an output of 749 kW (1019 hp) at 2100 rpm. The engines are IMO Tier III-certified and equipped with a Selective Catalytic Reduction exhaust gas aftertreatment system.

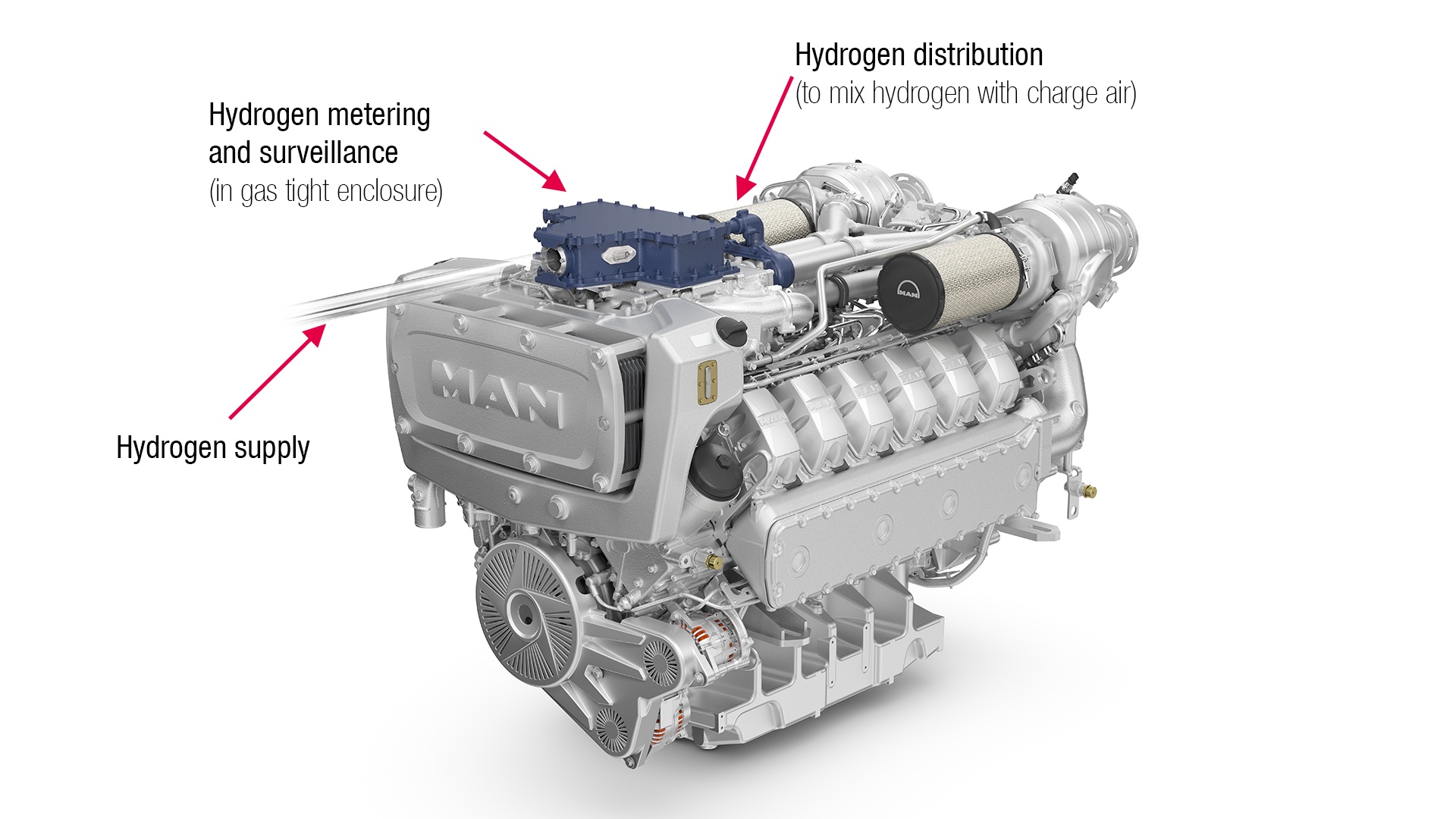

Both V12 engines have been prepared for dual fuel operation by MAN Engines, and supplemented with a hydrogen injection system by development partner CMB.Tech. The low-emission engine is used on the world’s first hydrogen-powered crew transfer vessel (CTV), the “Hydrocat 48” from Windcat Workboats.

“What’s special about our technology is that we use a conventional diesel engine, which doesn’t need to be optimised for hydrogen,” says Werner Kübler, Head of Development at MAN Engines. A proven V12 marine engine is thus used in which hydrogen is introduced into the charge air via an adapter and is added to the combustion cycle. The combustion process is thereby started according to the diesel principle, which requires the injection of approx. 5% of diesel fuel. The diesel fuel common rail injection parameters have been optimised here for dual fuel operation.

“MAN Engines has long-standing experience in the development of fuel-saving and reliable diesel engines, including for work boats. Building on this experience, we were also able to achieve the best consumption values in dual fuel operation, and ensure the same operating behaviour as displayed by diesel operation at full load. At the same time, we also reduce CO2 emissions through the use of hydrogen by an average of approx. 50%, and even up to 80% as a peak value,” adds Kübler.

MAN Engines: the advantages of the dual fuel hydrogen engine

A further advantage of using the conventional and sophisticated diesel engine is the accustomed easy handling when it comes to maintenance and service. Moreover, pure diesel operation can continue without interruption if the hydrogen supply is exhausted, for instance. Availability, driving comfort and operational safety are thus always guaranteed at the high level that a traditional diesel engine is known for.

MAN Engines offers its customers and partners solutions like the “MAN Smart Hybrid Experience” hybrid system or engines for gas/electric drives, to contribute to CO2 reduction and sustainable shipping. Now that the MAN D2862 LE448 dual fuel engines for work boats are ready for series production, a further milestone has been reached to that effect. “By starting with dual fuel combustion engines, we can make hydrogen technology operational in the industry and kick-start further development of the technology, regulation, supply chain, etc.,” says Willem van der Wel, Managing Director of Windcat Workboats.