MAN: methanol engines continue rise with major order

Hyundai’s shipbuilding division has ordered 6 × MAN B&W G95ME-C10.5-LGIM dual-fuel main engines in connection with the construction of 6 × 17,000 teu container vessels for A.P. Moller - Maersk, the Danish integrated logistics company. Hyundai’s engine machinery division will build the engines in Korea, which will be capable of running on green methanol.

Hyundai’s shipbuilding division has ordered 6 × MAN B&W G95ME-C10.5-LGIM dual-fuel main engines in connection with the construction of 6 × 17,000 teu container vessels for A.P. Moller – Maersk, the Danish integrated logistics company. Hyundai’s engine machinery division will build the engines in Korea, which will be capable of running on green methanol.

Bjarne Foldager, Senior Vice President and Head of Two-Stroke Business, MAN Energy Solutions, said: “The adoption of methanol propulsion is gaining pace, behind which there are several drivers. Crucially, MAN B&W methanol engines are available and proven with the first engines having already entered service back in 2016. Additionally, as a fuel, methanol can be carbon-neutral when produced from renewable energy sources and bio-genic CO2. The production capacity of such green methanol is currently increasing significantly; it is also liquid at ambient conditions, which simplifies tank design and minimises costs. Finally, our methanol engine only require a fuel-supply pressure of just 13 bar and a number of manufacturers already offer such fuel-supply systems today.”

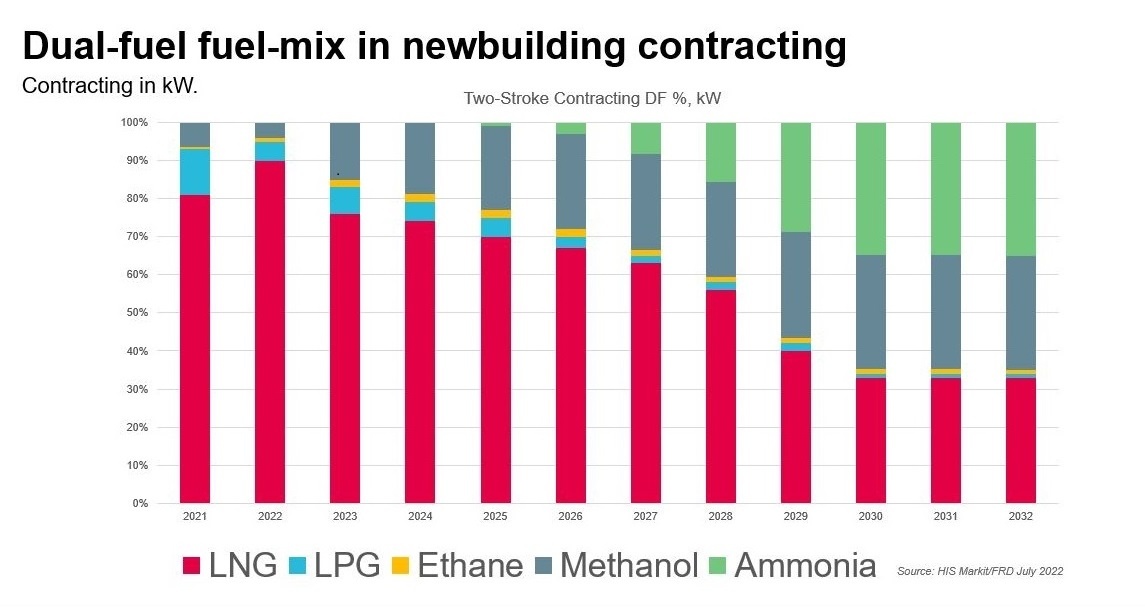

Thomas S. Hansen, Head of Promotion and Customer Support, MAN Energy Solutions, said: “We currently have a total order book for 78 ME-LGIM engines, of which 24 are firm orders for G95-variants. In addition, 19 of our 50-bore variants are already on the water and have accumulated more than 140,000 running hours on methanol alone. As a fuel, the future looks promising for methanol and we fully expect its uptake to encompass around 30% of all dual-fuel engine orders in just a few years from now.”

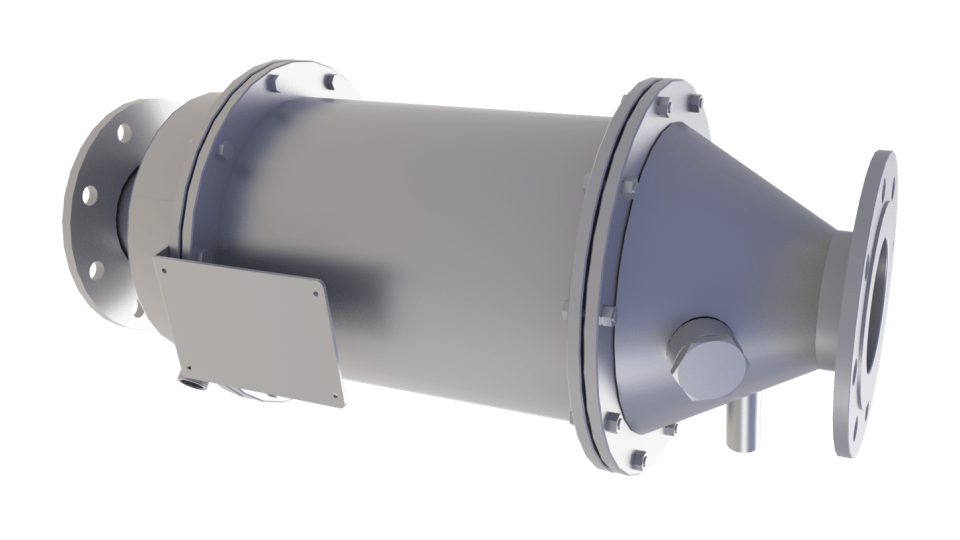

About the MAN B&W ME-LGIM engines

MAN Energy Solutions developed the ME-LGIM dual-fuel engine for operation on methanol, as well as conventional fuel. The engine is based on the company’s proven ME-series, with its approximately 5,000 engines in service, and works according to the Diesel principle. When operating on green methanol, the engine offers carbon-neutral transportation of large merchant-marine vessels.

MAN developed the ME-LGI engine in response to interest from the shipping world in operating on alternatives to fuel oil in order to reach decarbonisation targets. Methanol carriers have already operated at sea for many years using the engine, and, as such, the ME-LGIM has a proven track record offering great reliability and high fuel-efficiency.