Punch Hydrocells for Castagnola Yachts

Punch Hydrocells unveils plan on Hydrogen Internal Combustion Engine development with Castagnola Yacht

Punch believes in hydrogen, so much so that it has conceived a spin-off from its Italian subsidiary in Turin. Punch Hydrocells was born on June 1, 2021, and is completely independent and parallel to Punch Torino, with which it obviously shares synergies and engineering expertise. A total of 22 experts have been diverted to Punch Hydrocells, which will manage in house the capacity to develop hydrogen propulsion systems, ICEs and fuel cells, as well as hydrogen production, storage and distribution systems. The thinking goes back a long way, to the four-wheeled world: “If we talk about batteries for cars, this logic works, both in terms of mass management and range and recharging times. If, on the other hand, we’re talking about heavy transport, or in any case where the payload is the discriminating factor, then what’s the point of filling these applications with battery packs?”

Punch Hydrocells point of view

Stefano Caprio, head of Punch Hydrocells, explains at the Genoa Boat Show: “If a 44-tonne truck has to travel 800 kilometres today, it needs around 8 tonnes of batteries! This is another reason why we are convinced that commercial transport requires hydrogen to break free from the embrace of fossil fuels. The use of hydrogen as an energy carrier, as an alternative to batteries, combines very fast recharging times with low weight, thanks to the high gravimetric energy density of hydrogen.”

The electrical energy stored in the form of hydrogen can be stored for a long time before being converted to fuel cells or internal combustion engines. One of the critical issues with batteries, as most people know, is the disposal of lithium. In figures, then, the average capacity of a battery is 300-400 Wh/kg, while that attributable to hydrogen is 33,000 Wh/kg. Any problem? “Green hydrogen costs around 10 euros per kilo, so the competitiveness threshold must be reduced to around 3.5-4 euros per kilo,” replies Caprio. The medium- to long-term goal is green hydrogen. Blue hydrogen, derived from fossil fuels, exploits the principle of carbon capture, which allows carbon dioxide to be released in the form of carbon compounds or stored directly underground. This is followed by the conversion of the thermal engine, such as the General Motors V8 Duramax 6.6L photographed at the stand, for which Punch Torino is the official distributor for EMEA and APAC. A process that required the introduction of spark plugs and modifications to pistons, intake manifold and cylinder head. In terms of injection, the evolution underway in Turin is from port fuel injection, with injection in the intake manifold, to direct injection, which delivers hydrogen directly into the combustion chamber, which will improve efficiency and specific power. The storage kit is provided by Landi Renzo, Punch Torino’s partner in the bus project together with AVL Italia and the bus manufacturer IAA.

Talking about application. Castagnola Yacht

The time has now come to involve the application partner, certifying its presence at the Boat Show, Castagnola yacht, founded in Lavagna (Ge) in 1974 by shipwright Giovanni Castagnola.

Massimo Giraud, PUNCH Turin Key Account Manager, recalls: “the collaboration between PUNCH Turin and Castagnola Yacht was born just one year ago during the Boat Show; it was the classic love at first sight where the harmonious and elegant lines of Heritage met the power that the engines of the renowned American company are able to offer. This led to the idea of an ideal combination to land in America with the Heritage. From Genoa to the Atlantic coast of the States; good blood tells.

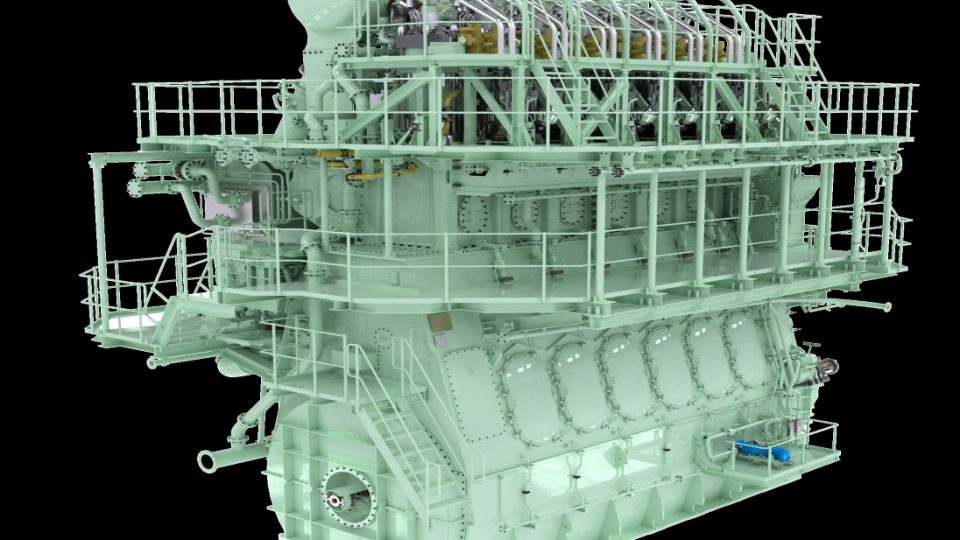

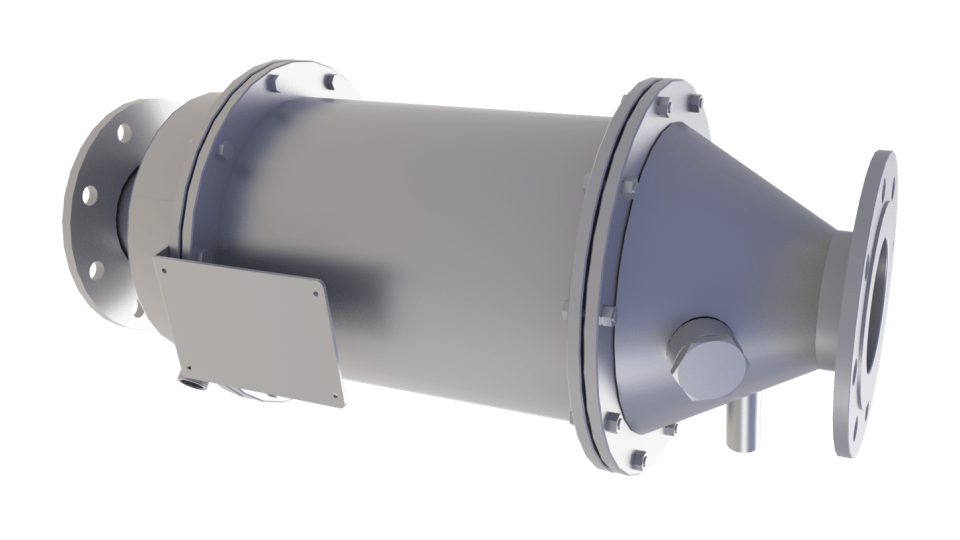

The first phase of the shipyard’s involvement therefore involves the installation of two GM-derived V8 diesel engines which will allow Heritage to easily exceed 50 knots, thanks also to the transition from the stern foot to surface propellers. The evolution of the Heritage vessel in 2023 will see a new version replacing the diesel engines with a single hydrogen-powered V8 supplied by PUNCH Hydrocells. This change was necessary to make room for four cylinders with a capacity of 18 kg of hydrogen each at a pressure of 700 bar. These cylindrical bodies, 700 millimetres in diameter and 1.9 metres long, are necessary to store enough fuel in a gaseous state to guarantee an autonomy equivalent to 250 litres of diesel fuel.”

In regards of this newly born collaboration, the CEO of Castagnola Yacht, Gabriele Maestri has stated: “Castagnola Yacht has decided to face the challenge of decarbonization by actively participating in the design and construction of a “Green” model of the Heritage boat. Our WTS production process will be further enriched with a new element to replace carbon. Combined with the hydrogen powered propulsion provided by PUNCH Hydrocells, it will allow us to offer the nautical market a completely ecological boat. PUNCH Group has understood the reliability and strong capabilities that characterize our innovative production, which has been ongoing since 1974 in our shipyard located in Lavagna (GE). We are aware that the path towards a more sustainable mobility is long and highly challenging, but we firmly believe that the dynamic approach of our company combined with our strategic partnerships will allow us to achieve great results.”