Rolls-Royce: an award and a new supply in Brazil

Rolls-Royce has won it the Environmental Technology Prize awarded by the Ministry for the Environment in the state of Baden-Württemberg.

The Rolls-Royce business unit Power Systems has developed a sliding bearing for its mtu engines that reduces their fuel consumption by 1%. That achievement has won it the Environmental Technology Prize awarded by the Ministry for the Environment in the state of Baden-Württemberg. The new bearings significantly reduce the amount of friction arising between bearing and crankshaft and also enable prediction of when maintenance will next be required.

The bearing surface, instead of being entirely smooth, is furbished with fine grooves, which, together with the lubricant, produce an aquaplaning-like effect which functions as an anti-friction layer. This anti-friction layer reduces, for example, the friction-induced losses arising between crankshaft and bearing by 20-35%, depending on the operating mode. The innovative bearing is the result of a collaborative effort between a small project team in Friedrichshafen, bearing manufacturer Miba, and the MontanUniversitätLeoben in Austria.

Use of the bearing in the engine reduces friction-induced losses, and while power output is maintained, fuel consumption drops by around 1%. That does not sound like very much, but a little goes a long way, as the following simplified example shows: a mining truck powered by a large engine whose power output is roughly equivalent to that of twenty medium-sized passenger cars runs for around 20 hours a day, consuming some 400L of fuel per hour under full load. Installed in the engine, the new bearing alone therefore enables a fuel saving of around 80L per day.

The bearing, for which a patent is pending, is not only suitable for use in mtu engines from Rolls-Royce. It is suitable for all equipment in which sliding bearings must withstand high loads – for example utility vehicle engines, turbines and wind power plants, which, thanks to the new bearing, go into operation a little more quickly than before and are therefore productive for longer.

Rolls-Royce to supply eight mtu engines for tugboats in Brazil

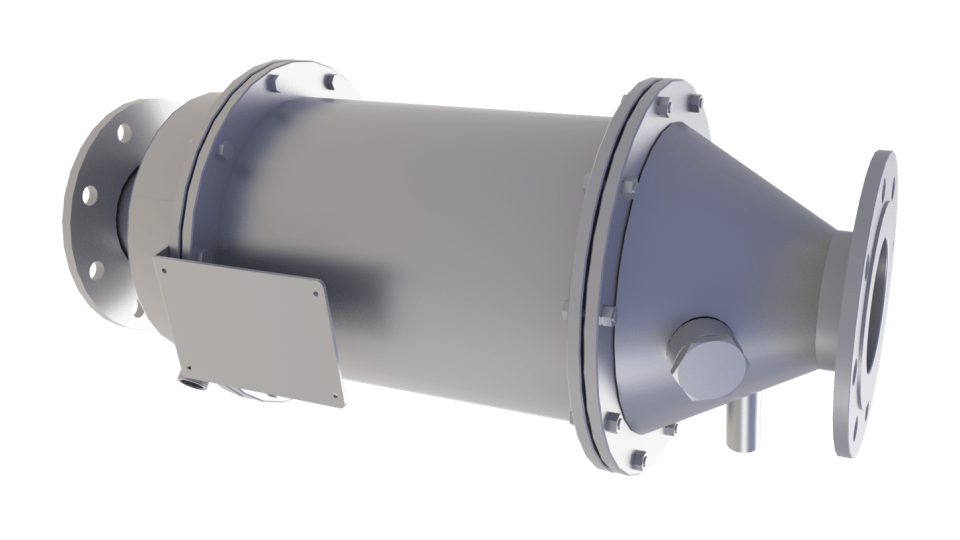

Rolls-Royce continues to expand its share of the tugboat propulsion market in Brazil: the company is supplying eight 16V 4000 M63 mtu engines to Brazilian shipyard Rio Maguari. The engines, each with an output of 2,000 kW, will power four new tugboats that Rio Maguari is building for the leading tugboat shipping company Svitzer. The engines will be delivered by May 2022. The four new tugs of the Ramparts 2300 series designed by Robert Allan have a bollard pull of 70 tons and are to be used in ports in Brazil. With the new vessels, Svitzer will operate a total of eleven mtu-powered tugs in Brazil. About one in five tugboats in Brazil operates with mtu propulsion.