AVL showed its hybrid and electric solutions

Marine hybridization for the reduction of operating costs AVL spends his expertise in engineered powertrains for all kind of applications, including hybridized propulsion in all marine ships. Growing public and regulatory attention on emissions demand significant improvement in fuel efficiency and soot emission, and AVL, with over 25 year’s experience in hybrid development, offers customized […]

Marine hybridization for the reduction of operating costs

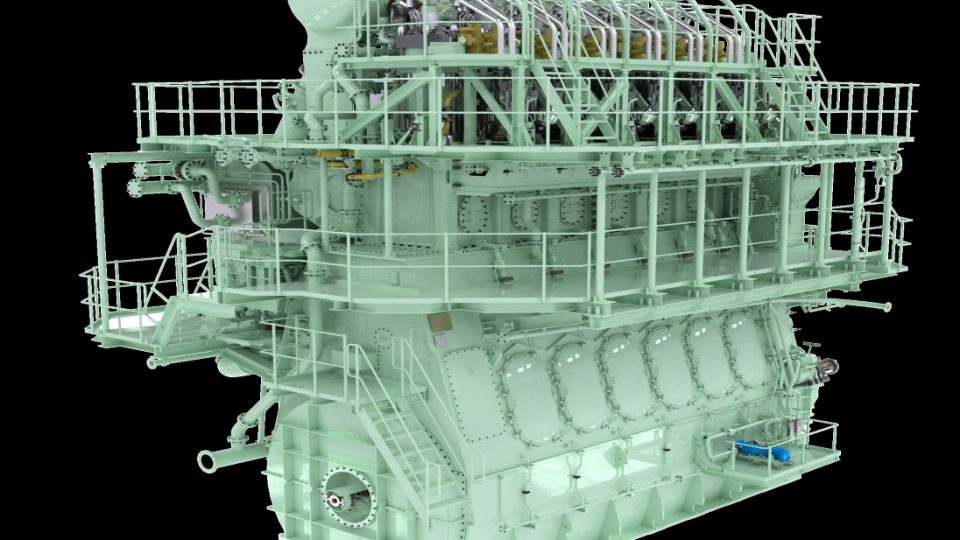

AVL spends his expertise in engineered powertrains for all kind of applications, including hybridized propulsion in all marine ships. Growing public and regulatory attention on emissions demand significant improvement in fuel efficiency and soot emission, and AVL, with over 25 year’s experience in hybrid development, offers customized hybrid and electrified solutions to match any vessel’s operating profile.

AVL AND HDGAS. THE FINAL EVENT IN TURIN @CNH VILLAGE

Thanks to AVL’s long-term experience with conventional propulsion systems and their hybridization the company is an reliable partner for any type of customized hybridization and electrification solution.

At Hamburg SMM AVL showed its new solutions about hybridization and electrification in marine market.

Looking through benefits of hybrid propulsion systems the most relevant are: downsizing main and auxiliary engines results in increased efficiency and lower emissions. Decreasing transient operation of the main engine with battery assist reduces greenhouse gas emissions and scrubber system size for the ECA compliance. Additional system redundancy and increased flexibility in ship architecture. At the end, thanks to an optimized operation strategy, other benefits are lower maintenance costs and reduced engine running hours.

Avl’s competences in hybrid and electrified marine applications cover battery enginnering, e-Drive design and software and controls development for all hybrid propulsion components.

AVL’s smart solutions and a carefully engineered hybrid system layout allow customers to address various requirements for marine propulsion.

MSSplus, AVL Micro Soot Sensor

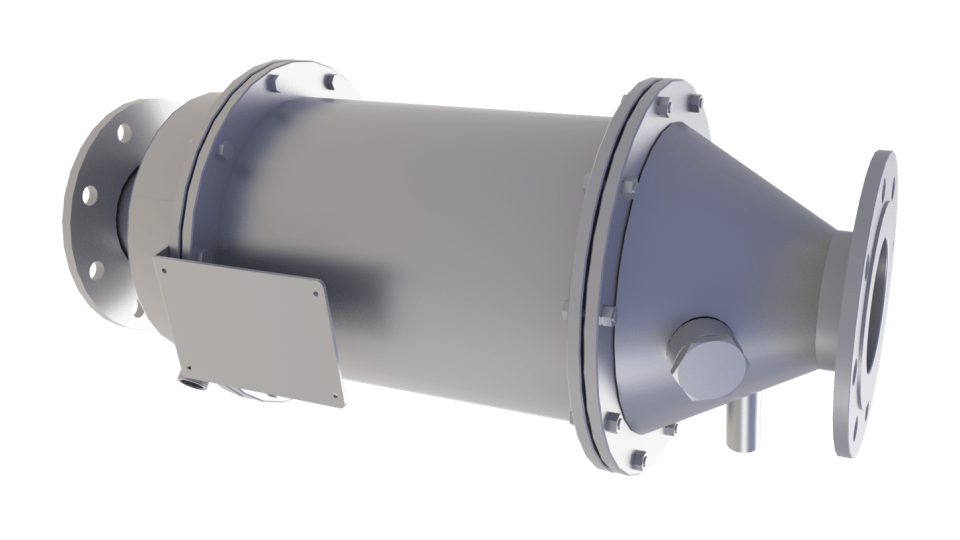

The MSSplus is the only measurement system in the market that is able to determine the concentration soot directly out the primary measurement value, without cross-sensitivity to other exhaust components like hydro-carbons, sulfates or NO2.

The MSSplus operates based on the photo-acoustic measurement principle. In this method an absorbing substance is irradiated with modulated light. The continuous warming an cooling and the resulting expansion and contraction of the carrier gas of the soot produce a sound wave which is detected with a microphone.

Clean air does not produce a signal. With soot-laden air or exhaust gas, the signal increases in proportion to the concentration of soot in the measured volume. Test results from several laboratories show very good correlations to gravimetric measurements.