Two-stroke engines and efficiency

Two-stroke engines have two important advantages over four-stroke engines in terms of efficiency

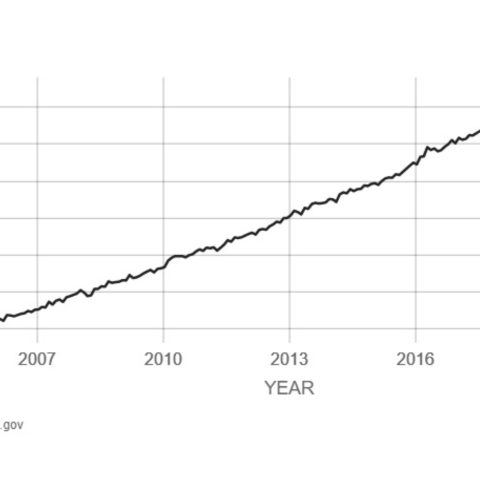

This article about the link two-stroke engines and efficiency sounds as the natural evolution of the previous research of Serguei Tikhonenkov, MSc. We propose to our readers the first part of the new script by Mr Tikhonenkov. During the last 5-8 years, global warming became clearly noticeable. This issue is alarming and attracts the attention of national governments and international organizations. NASA has published the latest measurements on July 2020 -414 PPM and chart ‘Direct measurement: 2005-Present’ (see the figure displayed).

Two-stroke: a way to enhance ICEs efficiency?

Moreover, IJER editorial – The future of the internal combustion engine – defined the problem clearly: The CO2 emitted from an engine is directly proportional to the hydrocarbon fuel consumed. On the other hand, the research of BP also has shown that the total share of the fossil fuels like oil and gas makes up about 60% of all primary sources of power and coal 20%. Thus, the world population faces with the problem that cannot be solved by using only the contemporary perfection level of internal combustion engines. Therefore, there is a vital demand – to find a new approach to reducing fuel consumption and, consequently, pollutants, including carbon dioxide emissions, and at the same time, to ensure prosperity and the high living standards. The research has shown that the main ways to reduce emission are «advanced combustion modes and innovative aftertreatment systems, including extensive use of catalysts and high-filtration-efficiency diesel and gasoline particulate filters (D/GPF) in the after-treatment system».

Talking about advantages and disadvantages

However, another path and a critical look at traditional internal combustion engines also deserve an attention. To determine the advantages and the disadvantages of modern engines, two-stroke and four-stroke engines are considered. Two-stroke engines have two important advantages over four-stroke engines: they produce about twice as much power and they are simpler because they don’t have the gas distribution mechanism. As to disadvantages, they consume significantly more oil and fuel because a new charge of the combustible mixture (a mix of fuel, oil and air) partially goes through the exhaust port into the environment. Modern two-stroke engines, likewise four-stroke engines, are built using the classical design: cylinder, piston, connecting rod and crankshaft, and several known disadvantages of conventional engines should be noted.

In details

1. An inefficient combination of pressure within the cylinder and tangential force on the crankshaft.

Two points need to be looked at closely here:

a) With the pressure increasing to a maximum and combustion of a significant part of the mixture, the crankshaft rotates 180 degrees, and the ratio of the tangential force on the crankshaft to the force acting on the piston varies from 0 to 1 and from 1 to 0.

b) Thus, two phenomena are observed when the crankshaft rotates 180 degrees: the pressure changes from a maximum to a minimum value (Figure 2), which coincides with an isothermal part (combustion stroke) of the Carnot cycle.

A polytropic process is described by the following equation:

P V n = constant

T = P*sin (a + B)/cos B

P = 1 – a force acting on the piston (conventionally assumed to be equal to 1).

T – a tangential force

The compressed mixture is ignited when the piston is at top dead centre (TDC). It is known that high temperature and high pressure are necessary for the complete and effective combustion of the air-fuel mixture. This condition is not met in traditional engines. After passing the TDC, the piston goes down. The space above the piston increases, and the pressure and temperature decrease, and the fuel-air mixture does not burn up completely and as result mix with the fresh portion combustible mixture. Mainly due to incomplete combustion, the exhaust gases also contain pollutant emissions. Therefore, we need to make our goal to overcome the above-mentioned flaws, namely, to create a new effective concept of the two-stroke engine. Three tasks need to be solved. At the TDC the piston must be stationary for a short time to ensure an increase of the pressure and temperature to the optimal values and also at the BDC to ensure the exhaust of the entire amount of burned gas. The intake and the exhaust ports must be separated to prevent the new charge of the combustible mixture (mix of fuel, oil and air) from escaping through the exhaust port into environment. The lever of tangential force on the drive shaft must be constant along the piston’s entire travel path. The idea of the new concept engine is to replace the crankshaft by chains that move linearly and drive the sprockets, creating a torque.