Doosan at bauma 2022 with the new DA45-7 dumper, powered by Scania

Doosan has several world premiere presentations planned for bauma 2022, including its new 4x4 articulated dump truck. The DA45-7, powered by Scania’s new 13-liter, was created to compete directly with the 40-ton class rigid dump trucks

Doosan has several world premiere presentations planned for bauma 2022, including its new 4×4 articulated dump truck (ADT). The new DA45-7 version was created to compete directly with the 40 ton class rigid dump trucks (RDT) and is the perfect complement to Doosan’s current range of ADT 6×6 market leaders, made up of Stage V-compliant DA30-7 and DA45-7 models with payloads of 28 and 41 tons, respectively.

In the new ADT 4×4, the tractor and cab are the same as the original 6×6 model and the changes focus on the trailer. Equipped with a ZF EP8-420 transmission, the DA45-7 4×4 is a two-axle ADT with twin rear wheels and a body section similar to that of the 40 ton class RDT.

Superior performance in tough conditions

“With superior performance on the roughest roads, on the smoothest surfaces and on the steepest terrain, our new 4×4 articulated hauler aims to challenge the 40-ton RDT by presenting itself as a machine capable of offering much more than chassis dump trucks. rigid traditional products,” explains Beka Nemstsveridze, Doosan Product Manager ADT.

In addition to ensuring superior performance in conditions that are difficult for normal RDTs, the new ADT 4×4 DA45-7 is less than 4m wide to avoid having to require special transport conditions and offers a better turning radius than similar RDT class. The smaller turning radius and tipper configuration, which is better suited to transporting flat and heavy rocks, offer particular advantages in tunnel construction and mining applications.

These are growth markets for ADTs and include pioneering and short-term mining projects and contract mining and quarrying operations, particularly in Southern Africa, the UK and Australia. Other major users of ADTs are companies involved in construction and earthmoving works for roads, dams, airports, landfills and real estate development projects. The combination of these sectors makes the ADT market large and diversified, guaranteeing a very large customer base.

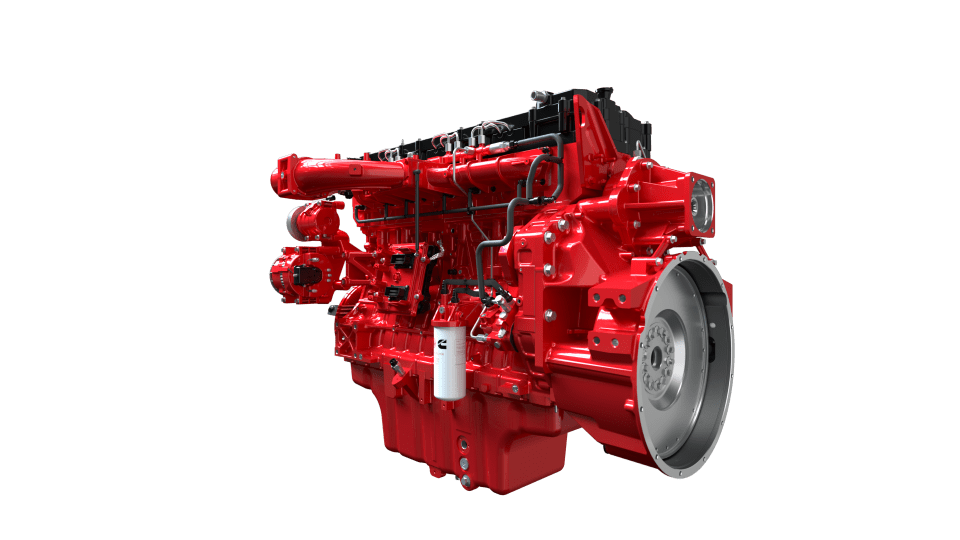

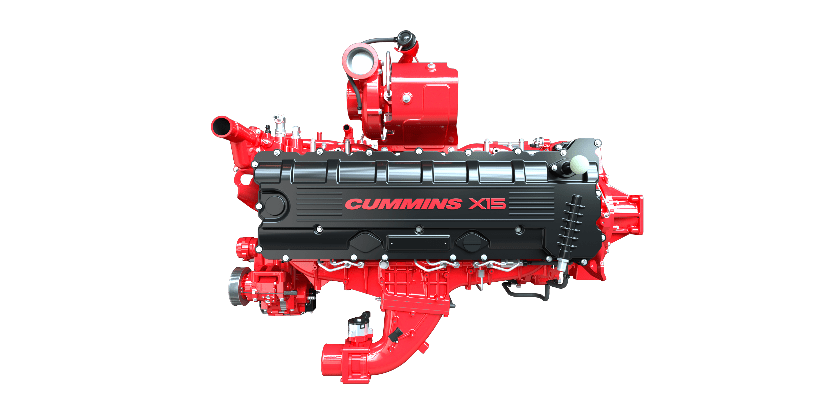

The DA45-7, developed at the Doosan ADT plant in Elnesvågen, near Molde, Norway, is powered by the new 13-liter Scania Stage V DC13 diesel. The new Scania engines have undergone two years of very intensive testing in harsh construction and mining environments and have passed with flying colors. Although the core of Scania engines, responsible for their exceptional reliability, has not changed, the main difference between the new engines from their predecessors is the improved after-treatment system.