Doosan DL580-5 wheel loader. The Diesel engine is from Södertalje

Doosan DL580-5 wheel loader and Scania DC13. Orange on orange… Doosan DL580-5 wheel loader meets Stage IV. The 5.7 m3 machine is powered by the Scania DC13 087A engine, 6 cylinders in-line, with 12.7 liters displacement, Variabile turbo geometry and XPI common ra il, managed by the EMS, Scania Engine Management System. On Tier IV Final EGR and […]

Doosan DL580-5 wheel loader and Scania DC13. Orange on orange…

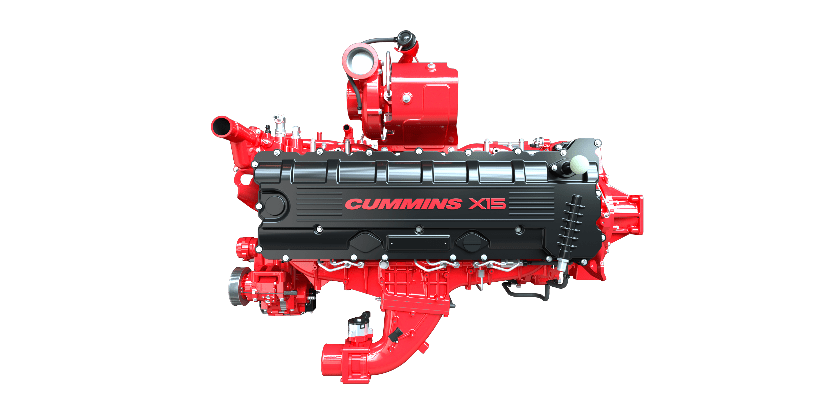

Doosan DL580-5 wheel loader meets Stage IV. The 5.7 m3 machine is powered by the Scania DC13 087A engine, 6 cylinders in-line, with 12.7 liters displacement, Variabile turbo geometry and XPI common ra il, managed by the EMS, Scania Engine Management System. On Tier IV Final EGR and SCR are still working with no DPF. Scania announced at Bauma 2016 the EGR will be removed from the Stage V engine architecture. The 12.7 liters-diesel engine provides 283 kW at 1800 rpm and 1765 Nm at 1300 rpm.

SCANIA DC16 AND THE MILLER CYCLE

The thermal engine works together with the ZF 5-gear transmission. From Passau also the ZF Type II axle with an automatic Hydraulic Differential Lock (HDL).

With a bucket capacity of 5.7 m3, the Doosan DL580-5 wheel loader has a similar look to the existing DL550-5 model, but features robust structural components and an advanced sophisticated double circuit axle cooling system to provide an ideal solution for applications such as block lifting and other heavier material-handling needs in industrial, construction, recycling, mining and quarrying applications.

Doosan DL580-5 wheel-loader has a weight of 36030 kg

To meet these requirements, the DL580-5 has an operating weight of 36030 kg and higher static tipping loads (straight/full turn 40°) of 29700 and 26200 kg, respectively. Like all Doosan wheel loaders, the DL580-5 is equipped with a Torque-converter-lock-up system which, when activated, is switched on automatically. The lock-up provides a direct drive between the engine and transmission, enabling 100% torque delivery without any loss from 2ndgear up to the top 5thgear.

The Doosan ‘family feeling’ is due last to the load sensing hydraulic system, whereby the variable axial piston pump generates the flow upon demand in the amount necessary to perform the work.

The exhaust and after-treatment system for the engine is installed on the left-hand side of the machine, whilst the components for maintenance are grouped on the right-hand side. All the daily checking of gauges can take place from ground level to ensure it is a quick and safe process. Doosan has also installed an automatic greasing system as standard to reduce working time and increase operating comfort. To facilitate access and mobility on the machine, multiple hand-rails ensure that the operator always has a firm support to hold on to.

Lockable steel cap for the oil filter

The wheel loader features a new lockable steel cap on the transmission oil filler, the shape of which has been changed to allow it to be locked with a padlock. When the transmission oil filler tube is locked, the transmission oil cannot be polluted with other types of oil or liquid, dust and other substances. It is also an additional guarantee of security for the customer.

ALL THE DOOSAN FLEET IN A CLICK

The efficient all aluminium cooling system is separated from the engine compartment to prevent warm and dusty air from entering and to allow better control of the air intake. An automaticallyvariable-speed reversing fan is a standard feature providing the best possible cooling while optimizing fuel consumption. The radiator fan is hydraulically driven and controlled by an ECU. Changing the fan direction for cleaning the radiator can be done manually from the cab, without having to switch off the engine. Fan reverse intervals (30 minutes to 2 hours) can be set via the menu.