John Deere and Liebherr. Thinking big

John Deere and Liebherr. It is of these days the official presentation in Waterloo, Iowa, which puts Liebherr in the Olympus of the great Diesel engines manufacturers. Bulle’s D9512 (the name of the Swiss village where the factory is) replaced Cummins’ QSK19 under the hood of the American harvesters. John Deere and Liebherr John Deere and […]

John Deere and Liebherr. It is of these days the official presentation in Waterloo, Iowa, which puts Liebherr in the Olympus of the great Diesel engines manufacturers. Bulle’s D9512 (the name of the Swiss village where the factory is) replaced Cummins’ QSK19 under the hood of the American harvesters.

John Deere and Liebherr

John Deere and Liebherr. 3 to 4 for 9000 series powertrain

The 9000 series trenches will be available from spring 2019. Four machines are available, in progressive order of power (9600, 9700, 9800 and 9900). The low entry one is still captive, with the top of John Deere Power Systems, the 13.5 liter 460 kilowatt.

DEERE ON THE STAGE V: FROM 13.5 @ 460 kW TO 13.6 @ 500 kW

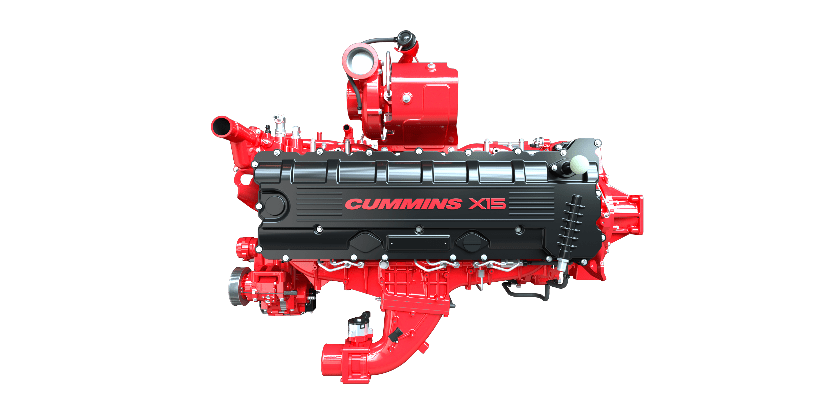

The other three units adopt the 566, 640 and 713 kilowatts ratings (770, 870 and 970 HP) of the D9512 engine. Compared to the new engine platform conceived with Deutz, the 24,2 liters reproposes the two liters single cylinder displacement (BxS 128×157 mm) that powered MAN trucks and has been a best seller for several years in the cogeneration field.

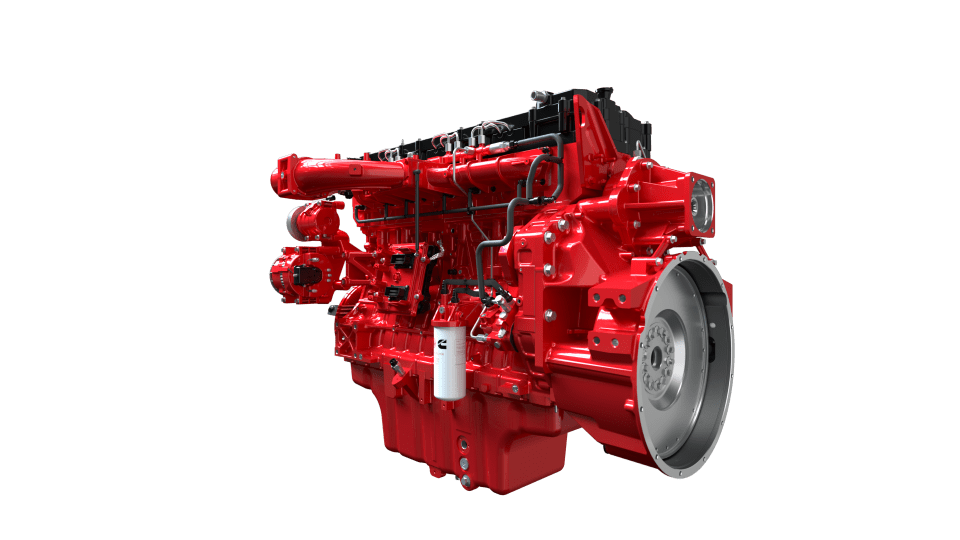

At the top of the hierarchy of the D9512 there is the 750 kilowatts to 1,900 rpm rating and 4,675 Newtonmeters. The white monoblock, manufactured in Switzerland, has overthrown the QSK19 by Cummins. The reasons for this choice are also to be found in the exhaust emissions strategy, based on the only SCR system, without even the support of a DOC. The harvesters, moreover, concentrate the peak of work in a ‘small slice’ of summertime and can not tolerate back pressure signals or a compromising wear of the cylinders. After the Krone BiG X880, the agreement between Liebherr and John Deere another harvester in the Swiss-German portfolio with a name whose echo is felt all over the world.

LIEBHERR DIESEL ENGINES. THE RISE OF A NEW STAR

Mike Weinert said

«John Deere Power Systems and Liebherr are both world-class engine designers and manufacturers who have a long history of successful interactions with each other,» said Mike Weinert, John Deere Power Systems vice president responsible for engine engineering and manufacturing. «Because of the capabilities each brings, and the long standing, positive working relationship, it makes sense for our two companies to join technical efforts in areas of engine technology and architectures, component sourcing strategies, and best practices related to engine development and manufacture».

9000 Series. Some features

The new 9000 Series trenches are distinguished by an advanced design characterized by elements of absolute novelty including, for example, the redesigned hulls and the double engine exhausts. Under the advanced livery, Liebherr engines, combined with other efficiency enhancing developments such as optimised component speed at low engine speeds, form the basis of John Deere’s HarvestMotion concept to significantly increase efficiency and optimise fuel consumption.

The 850mm crop flow was developed to support the extraordinary hunger of these machinery, ensure the best forage quality and cutting efficiency. Consistent with the increased power of the engines, the new trenches are equipped with a reinforced transmission and an improved chassis. The reliable DuraDrum rotor with a diameter of 670 millimetres can handle large product flows regardless of the set cutting length.