Perkins Eima. Syncro and 1706

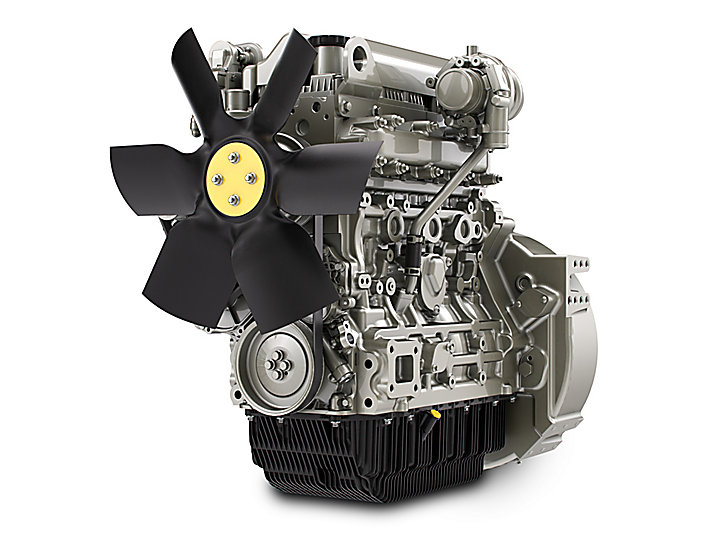

Perkins Eima and the compact engine Perkins Eima. The 3.6 litre engine from the British Syncro family, showed at Eima 2018, is designed to provide robust and adaptable power solutions for compact construction, agriculture and industrial machines. This engine is equipped with the after-treatment system placed above the top cover, to simplify the package fitting under the tractor hood, […]

Perkins Eima and the compact engine

Perkins Eima. The 3.6 litre engine from the British Syncro family, showed at Eima 2018, is designed to provide robust and adaptable power solutions for compact construction, agriculture and industrial machines.

This engine is equipped with the after-treatment system placed above the top cover, to simplify the package fitting under the tractor hood, considering as an example the agricultural applications. It has the same ratings as the core products, but it shows up as an all-in-one package. Perkins Eima strategy has the goal to provide OEMs with an all-in-one solution with no additional components needed. One important customer has already chosen to mount a prototype of this particular engine for testing, but as of Eima 2018 it was still unnominated.

So, the key aspect that comes with the 3.6l is the possibility to receive the whole system connected to the engine in one package, that the receiver can simply install in one place with no particular additional efforts required.

The engine offers OEMs the flexibility to meet different emissions standards, including Stage V, while maintaining a common machine design. OEMs will be able to access multiple territories without designing completely different engine installations. The 3.6 litre delivers 100 kW and up to 500 Nm of torque, with a rated speed between 2200-2400 rpm.

Production for this engine is expected to begin in early 2019, firstly for construction machineries and than it will also reach the agricultural sector towards early 2020.

PERKINS AND POWER GENERATION AT MEE DUBAI

What about the 1706?

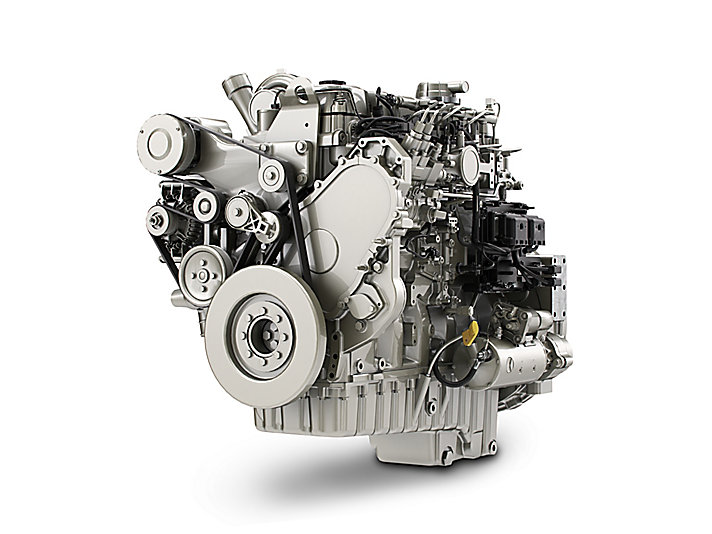

The 6 cylinder 1706 model is a 9.3 litre turbocharged and aftercooled unit with direct injection and a fully electronic control system. With a power range of 250-340 kW (335-456 hp) it’s the ideal choice for hard-working applications, particularly in construction.

Engineers at Perkins had the chance to do an in-depth work with this engine and they were able to redevelop the after-treatment system, removing Egr. The NOx reduction is done with SCR on this particular engine. Perkins focuses on adapting the right type of technology to the right type of engine for the right type of situation and with this in mind they also proceeded to make both the engine block and the after-treatment system smaller and lighter, with improvements on the air and combustion systems.

While keeping the dimensions small, this engine shoes up with an increased power density that enables OEMs to downsize their engine platforms and optimize cooling packages without sacrificing performance. The downsizing not only creates additional space to optimize machine installation for operator usability, but it also reduces running costs.

MORE NEWS FROM PERKINS: STEVE FERGUSON IS THE NEW PRESIDENT, AFTER YOUNESSI