Syn Trac, a multifunctional vehicle for every need

A new solution that takes the concept of versatility to its extreme consequences comes from Austria. Top handling, automatic hooking/unhooking systems and lots of technology. Powered by the 6-cylinder Caterpillar CAT C9.3B.

Infinite Possibilities. The subtitle that Syn Trac has chosen to place to complete its logo, a flower with four mirrored petals in the shape of an infinity, perfectly represents the philosophy with which its flagship vehicle was developed: an isodiametric designed for total versatility, able to adapt to different contexts of use, thus being able to become now a backhoe, now a telescopic handler. No, the Transformers have nothing to do with it and we are not crazy: the machinery developed by the Austrian manufacturer from Bad Goisern (Upper Austria), as confirmed by the producers, was created with the intention of satisfying the plurality of needs and tasks that characterize contemporary agricultural enterprises, from moving hay bales to sowing fields, all in a single work tool.

A plurality of functions –road maintenance, transport and so on – which obviously requires the use of dedicated tools, which can be installed on the Syn Trac (the vehicle has the same name as the manufacturer) thanks to a fully automated and symmetrical front and rear attachment/detachment system.

Activated with the touch of a simple button in the cab, the system is able to decouple the hydraulic system, pneumatic system, cardan shaft, electrical system and software from the tool in just under a minute, and it does not require the help of the operator, who can therefore remain seated comfortably in the cabin.

Syn Trac, powered by Caterpillar

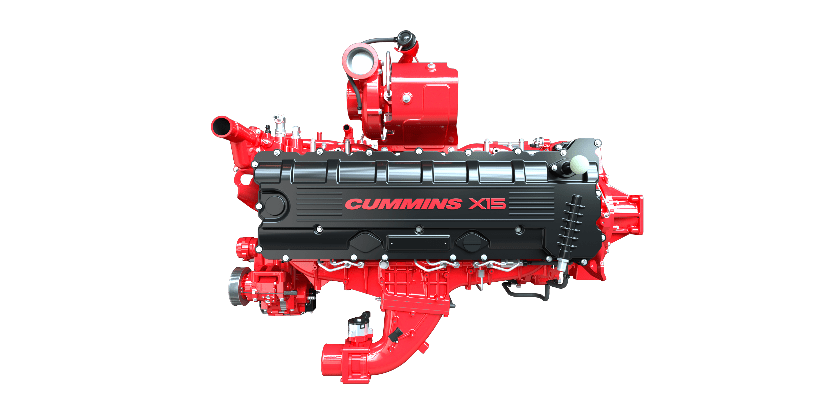

The 9.3-liter Stage V propulsion system, installed directly under the cab (hence the unusual shape of the Syn Trac), is a 6-cylinder Caterpillar CAT C9.3B (below) capable of delivering 420 hp and a maximum torque of 1,900 Nm at 1400 rpm. The CVT gearbox and the hydromechanical transmission guarantee two main speed regimes, a slower one (between 0 and 60 km/h) and a faster one (between 0 and 80 km/h). The standard hydraulic pump delivers 180 l/min at 210 bar and, optionally, up to 360 l/min. The Syn Trac also includes a load sensing axial piston pump of 180 l/min and 250 bar with 6 double-acting valves of 120 l/min on the front and rear coupling system. While the content of the hydraulic tank is 120 liters, that for diesel is 420 liters (with AdBlue at 35 liters): values that guarantee a wide operating autonomy to the vehicle.

Safety first

The cab is entirely covered with glass panels and the positioning above the propulsion system guarantees greater visibility compared to classic tractors, allowing a constant view of the automatic attachment/release systems of the implements. While the steering column is adjustable in three directions, the driver’s seat, which can be rotated, is available in two versions: one with a high backrest and the other with a lowered backrest. On the infotainment side, there are two operating panels, one of 7” and the other of 12”, a radio with CD player, USB, Bluetooth, with the possibility of using the speakerphone. The picture is completed by the automatic climate control system and the heating system for rear-view mirrors and windscreen (but available only as an option). Therefore, characteristics of great handling and visibility which, combined with the automation of the management of the tools, raise the concept of safety, central to the entire development of the Austrian vehicle, to power.