Volvo Penta-powered Magni is high achiever in NYC

Magni telescopic handlers are an alternative to tower cranes, thanks to their compact and powerful Volvo Penta industrial engines

With many of the 20,000 buildings erected in New York City each year standing on narrow or congested streets, there’s no room for complacency as contractors endeavor to minimize the disruption they bring to the neighborhood. Sometimes, there’s little room for tower cranes either – but, thanks to the powerful reliability offered by a Volvo Penta D5 engine and a Magni RTH 6.46 rotating telescopic handler, one company has found the perfect alternative.

“Space is at a premium and speed is essential,” explains Mick Duffy, Director of Field Operations, Structure Tech, which was contracted to build the 40-story structure on 47th Street. “We pour a concrete floor every three days, which is incredibly fast compared to other cities, but that’s New York: everything here is about time and money.”

Unlike a crane, the Magni RTH 6.46 rotating telescopic handler can be set up within minutes and easily moved, perfectly combining compact mobility and maneuverability with its status as one of the highest-reaching telehandlers in the world. Impressively, it can lift a maximum 6 t, or 2.5 t to just under 46 m, from where a spider crane can distribute the loads to the higher floors.

The telehandler is used for hoisting everything from plywood sheets to the concrete pump and bringing the garbage back down. It is estimated that the Magni will make approximately 3000 lifts over the 13-month build, including moving a total 900 t of steel. This sort of intensive use is far from unusual for Magni’s telehandlers, so when it came to choosing an engine that could reliably power the RTH 6.46, its engineers instantly thought of partnering with Volvo Penta.

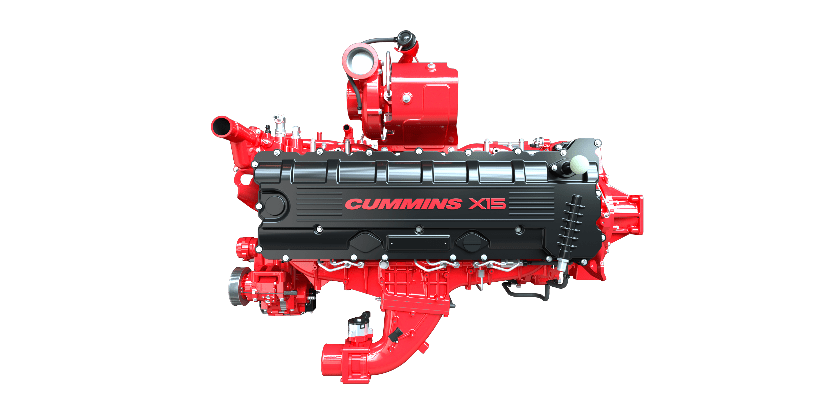

A perfectly integrated engine

The Modena, Italy-based OEM worked closely with Volvo Penta to develop a solution that met the machine’s unique challenges – namely reaching a good balance between size and power output. By producing a maximum torque of 910 Nm at just 1,410 rpm, and maintaining that all the way up to its 160 kW (218 hp) rated power at 2,300 rpm, the in-line 4-cylinder, 5.1-liter Volvo Penta D5 industrial engine quickly became the prime candidate.

“Telescopic handlers are quite small vehicles, and the specific power ratio that Volvo Penta’s D5 engine can provide allows Magni to reach its performance objectives despite the reduced footprint in the machine,” states Matteo Mambelli, Volvo Penta Italy.

Thanks to the D5’s compact dimensions – resulting from a reduced cooling capacity requirement – Volvo Penta and Magni engineers collaborated closely to ensure the TAD 572 VE Tier 4 Final engine was able to fit within the tight confines of the engine compartment and meet the requirements of the US market.

Their efforts soon revealed the need for the engine to be tilted, creating further challenges, such as ensuring that performance and reliability remained optimal. The testing period was therefore extended to confirm that the D5 would continue to run without issues in every condition.