When to use cogeneration according to Centrica Business Solutions

Before analyzing its potential, it is appropriate to give a definition of what is meant by cogeneration. When we talk about cogeneration (CHP) we talk about the process of converting a single fuel into both electricity and heat. All through a single process that takes place at the same point of use. Cogeneration is now […]

Before analyzing its potential, it is appropriate to give a definition of what is meant by cogeneration. When we talk about cogeneration (CHP) we talk about the process of converting a single fuel into both electricity and heat. All through a single process that takes place at the same point of use.

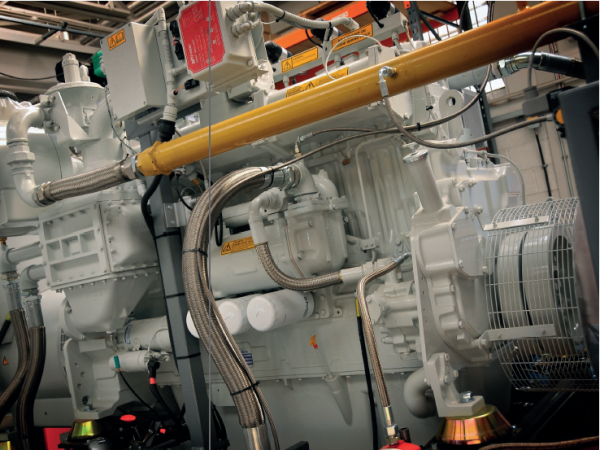

Cogeneration is now a rather mature technology, becoming part of sustainable alternatives to traditional centralized generation. In cogeneration solutions, an engine normally powered by natural gas works together with an alternator that produces electricity. Making the most of the fuel and converting it into electricity with an efficiency of around 35% and in heat with an efficiency of around 50%.

The advantages of cogeneration according to Centrica Business Solutions

Reduction of operating costs. In terms of reducing the real energy costs of the plants, the possibility of enjoying special incentives and stabilizing energy costs for a prolonged period.

Security of supply. As a cogeneration system works as an emergency generator, it provides emergency heat and reduces dependence on the grid.

Reduction of CO2 emissions. These plants generally produce reduced emissions compared to the traditional separate supply of electricity and heat, supplied by the network. The impact can be assessed by SBEM or other energy performance modeling software packages.

When to use cogeneration

Before determining the correct dimensions of a cogeneration unit, it is necessary to collect some data relating to the site. The main requirements focus on the consumption of site supplies (electricity and natural gas) and on the related tariffs. The most common source of this data is simply the bills for site supplies.

After collecting the data, it is possible to carry out a simple evaluation of the feasibility of the plant. The valuation is based on the calculation of the “energy spread”, ie the difference between the tariff of the electricity network and that of natural gas. If the network electricity tariff is 9 c/kWh and the natural gas tariff is 3 c/kWh, the energy spread is 3.0 (so a simple division is enough). As a general rule, an energy spread of at least 2.5 is necessary for a cogeneration scheme to be advantageous.

In determining which is the best cogeneration unit for a site, it is necessary to maximize both the electrical and thermal use of the production. If the cogeneration unit selected is too small, the maximum possible savings will not be realized, if on the other hand the cogeneration unit is too large, it will work inefficiently at partial load, with less hours of operation and values of use reduced.

The cogeneration system should work to prevent the dissipation of excessive heat and discourage the use of the units as simple gas generators.

WHITE HARVEST AND 2G TOGETHER FOR CLEAN COGENERATION

A look at installation costs

To deepen the evaluation it is necessary to examine also the characteristics of the site. So as to guarantee the suitability of the cogeneration system interface, to establish that the connective loads can actually be realized.

Installation costs can vary greatly from one site to another, mainly based on the following factors: location of the cogeneration plant, gas availability, space distribution, implications for building restrictions, noise problems, local regulations, limitations maintenance, electrical connections, thermal integration.

The most suitable sites generally have a demand for heat or refrigeration throughout the year, allowing the unit to be used as a “main boiler”.

Among the other local factors to be verified are the presence of people on the site and the hours of activity planned for the plant, the efficiency of the existing boilers and the future energy requirements that can be covered.