MAN ES to take part in research project on greener energy storage solution

North Rhine-Westphalia invests in development of electrothermal energy storage solution together with MAN ES. The German state is providing funding of 200,000 euro for a technical and economic evaluation study of the new MAN ETES energy-storage technology. RWTH Aachen University, Stadtwerke Aachen Aktiengesellschaft (STAWAG) and MAN Energy Solutions – the project partners – want to […]

North Rhine-Westphalia invests in development of electrothermal energy storage solution together with MAN ES. The German state is providing funding of 200,000 euro for a technical and economic evaluation study of the new MAN ETES energy-storage technology. RWTH Aachen University, Stadtwerke Aachen Aktiengesellschaft (STAWAG) and MAN Energy Solutions – the project partners – want to investigate the potential for implementing the technology in NRW. The study will examine the necessary requirements for constructing a research facility in the Aachen area in 2021. An electrothermal electricity storage system with a capacity of up to 7 MW is planned.

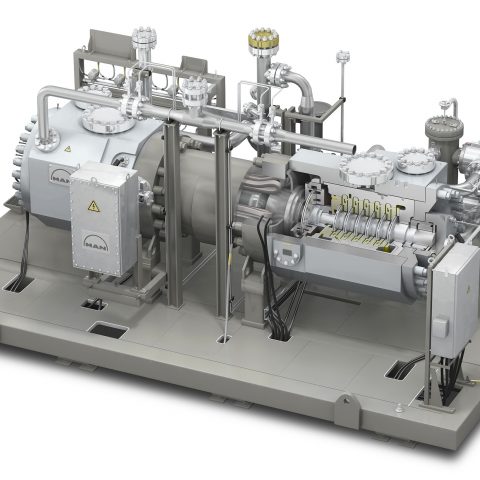

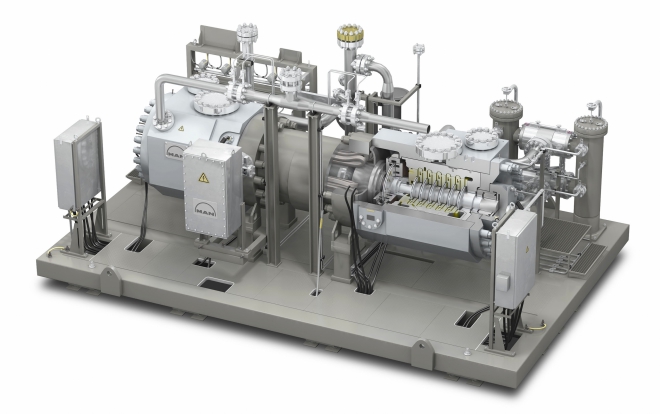

MAN ES for energy storage: ETES technology

The basic principle of ETES technology is the reversible conversion of electrical energy into thermal energy, which is stored in the form of hot water and ice in insulated reservoirs. A special feature of the electrothermal process is the added – or even preferable – possibility of distributing the heat and cold generated to users depending on demand and margins, and accordingly offering the option of converting it back into electricity as an additional usage variant.

The technology fulfills two important tasks: on the one hand, it helps with maintaining the grid balance by absorbing large amounts of surplus electricity from renewable energies and feeding it back into the grid when needed; on the other, the system integrates several sectors by generating, storing and providing thermal energy for heating and cooling purposes.

EGR offered for dual-fuel ME-GA engine

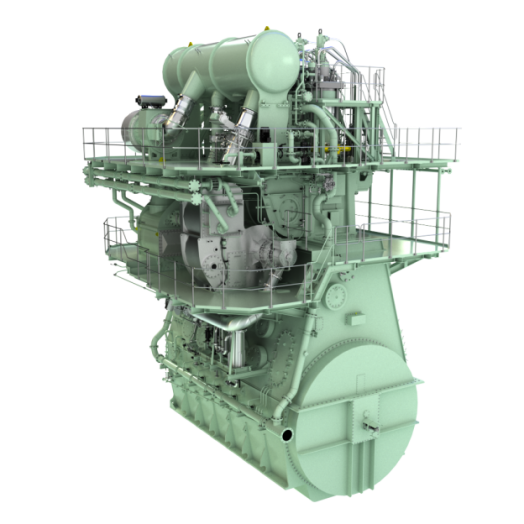

MAN ES has also announced that it is to offer its proprietary EGR system as an emissions solution for its new, low-speed ME-GA engine, the Otto-cycle variant of its established ME-GI dual-fuel engine. EGR is a NOx-emissions-reduction technique that ensures IMO Tier III- compliance in both diesel and gas mode.

«Nine years have passed since our very first EGR system passed its Factory Acceptance Test, and the knowledge we have subsequently gained in the field has led to today’s fully-mature solution. Our EGR system not only achieves NOx-compliance, but also delivers a performance upgrade for both conventional and now ME-GA engines», said Thomas S. Hansen, Head of Promotion and Customer Support, MAN Energy Solutions.

MAN Energy Solutions reports that EGR will enable the ME-GA to reduce specific gas consumption by 3 percent, and specific fuel-oil consumption by 5 percent. It will also significantly reduce methane slip by 30 to 50 percent and solve the issue related to pre-ignition on Otto-cycle engines.