Wärtsilä will supply power plants to Mexico and Nigeria

Wärtsilä will supply Mexico’s state-owned electricity utility with two large multi-fuel power plants and a captive power plant for a cement production plant in Nigeria

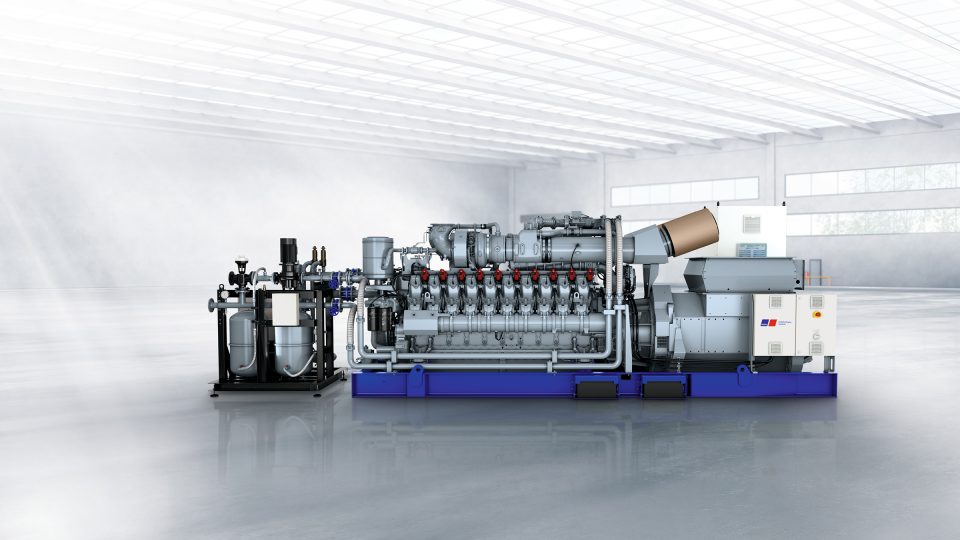

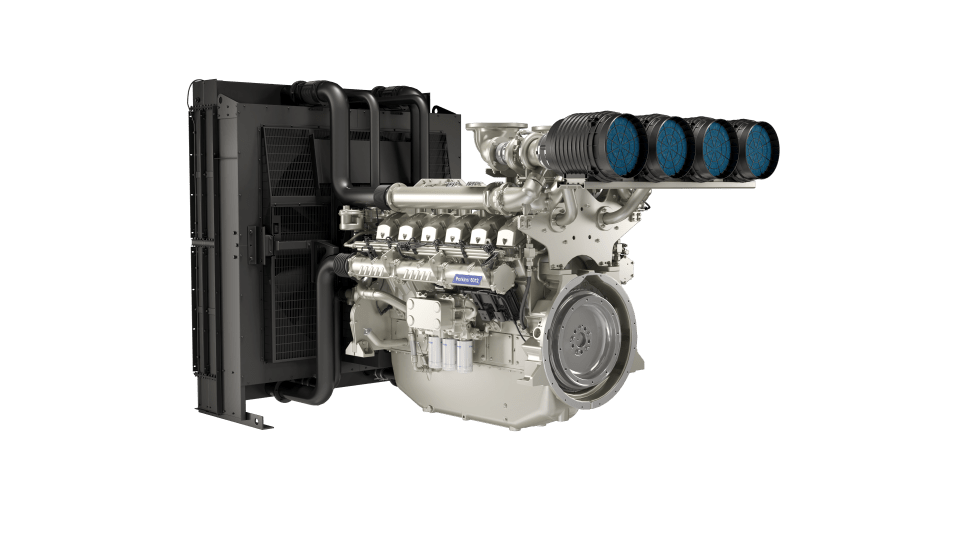

Wärtsilä will supply Mexico’s state-owned electricity utility with two large multi-fuel power plants and a captive power plant for a cement production plant in Nigeria. The two large multi-fuel power plants in Mexico will provide a combined output of 600 MW. The projects will be delivered by Wärtsilä on a full engineering, procurement, and construction (EPC) basis and are to be completed during 2022 and 2023. Jointly these projects represent the largest generating capacity EPC contract ever awarded to Wärtsilä. The projects comprise a 400 MW facility, the Mexicali Oriente power plant located in Mexico’s Baja California state, and the Parque Industrial plant, a 200 MW generating unit located in Sonora, Mexico. The Mexicali Oriente plant will operate with 24 Wärtsilä 50DF dual-fuel engines, while the Parque Industrial plant will feature 22 Wärtsilä 34DF dual-fuel engines. The engines will operate primarily on gas with the capability to use liquid fuel as a back-up if required.

The awarded projects provide a clear indication of the demand that exists for power plants of this size operating with flexible internal combustion engines. During the summer months the plants will operate continuously, meeting the high electricity demand in the region, when temperatures can reach +50 °C. For the remainder of the year they will be used to provide grid balancing service.

“Wärtsilä’s experience with EPC deliveries, its ability to deliver on a fast-track basis, and the efficiency of the company’s engine technology were key considerations in the contract award,” commented Risto Paldanius, Vice President, Americas, Wärtsilä Energy. “The power plants will serve the local needs today, and they will adapt to future needs.”

Wärtsilä technology for Nigerian cement producer

A 70 MW captive power plant for the BUA’s new Sokoto cement production plant in Nigeria is required to supply the energy for an off grid additional cement production line. This follows an order for a 50 MW power plant from the same customer just two years earlier. This latest extended engineering and equipment order was booked in Wärtsilä’s order intake in October 2021. Both the current and 2019 orders feature Wärtsilä 34DF dual-fuel engines operating primarily with liquefied natural gas (LNG), but with the flexibility to switch to an alternative fuel oil should there be interruptions to the gas supply, quality or pressure. Operation of the Wärtsilä engines is not affected by these interruptions.

BUA Group, through its cement subsidiary, is one of Nigeria’s largest cement producers with operations spread across Nigeria. In addition to the environmental sustainability benefit, it is estimated that the Wärtsilä solution will result in fuel cost savings of approximately 30 percent compared to the existing power plants operating on heavy fuel oil (HFO). Furthermore, the operational flexibility of the Wärtsilä engines provides future-proofing advantages enabling the potential use of energy from renewable sources, such as solar and wind. Wärtsilä holds a strong position in Nigeria’s power generation market. Together with its installed base, this and other orders will bring the company’s share to more than 800 MW. On the African continent as a whole, Wärtsilä has an installed base of more than 7000 MW.