AEM Cummins and sustainability

AEM and Cummins believe in sustainability. AEM has announced the creation of a Sustainability Council. The thought of Brian Mormino, executive director -- technical and environmental systems for Cummins

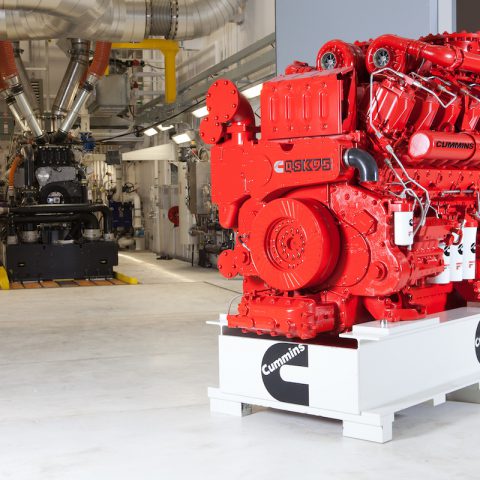

AEM and Cummins, like Diesel International, believe in the real sense of the word sustainability. We’ve developed the SPT, which will have its first stage ‘on the water’ on Thursday, April 22: “Unplagged Hybrid“. AEM has announced the creation of a Sustainability Council, among other things. For AEM member company Cummins Inc., Brian Mormino is the executive director of technical and environmental systems.

AEM Cummins and sustainability. Mormino said

«And it’s because of these growing trends and the sense of urgency associated with them that we’re seeing growing regulatory requirements,» said Brian Mormino, executive director – technical and environmental systems for AEM member company Cummins Inc. «That’s creating quite a burden for manufacturers around the world. How, exactly, are we going to deal with that?» Mormino shared his thoughts on regulations, sustainability and the impact of both on the equipment manufacturing industry at AEM’s most recent Product Safety and Compliance Seminar, held earlier this year.

AEM Sustainability Council

AEM has announced the establishment of a Sustainability Council comprised of leaders from member companies. The council will help advance member companies’ efforts in addressing issues of sustainability and to provide a framework for the adoption of best practices and innovation. If one thing’s for certain, it’s this: Manufacturers today need to be willing and able to ask and – perhaps more importantly – answer difficult questions about society, a sustainable future and the world around us all. «We have to drive ourselves to open our eyes, look at all the factors going on around us, and understand where we need to be focusing our time, effort and resources,» explained Mormino. «All of the issues we face today certainly have an environmental slant, but they impact us in so many different ways.»

Four steps

According to Mormino, manufacturers can go from a reactive to proactive state in four simple steps: Data is critical to making informed decisions and prioritizing how to proceed. Being able to focus on what is important is critical to determining potential impacts. «Part of our impact is what we buy, the impact it makes, and then the impact to make it,» said Mormino. «It goes all the way through to when our products are in use. There’s an impact from our customers using our products. And when you take that broad perspective, it really changes where you should be focusing your attention». «Don’t let data – or any other factors – prevent you from taking action and setting commitments,» said Mormino. «Sometimes you need to make the commitment and figure it out later.» In 2006, Cummins established its first-ever public environmental goal, one which called for a reduction in GHG emissions from its facilities. It was a bold goal, and one company officials weren’t exactly certain how to go about achieving. «But we knew it was the right thing to do,» said Mormino. «We did some benchmarking and collected some data, and we were comfortable enough with the idea that this was an important focus for us. Ultimately, we just needed to get on with it. And by telling the world about it, by saying ‘Here’s what we’re going to achieve,’ it would hold us even more accountable and focus even more of our resources.»

The end goal, he continued, is to begin to internalize environmental externalities by making sustainability a part of business operations as a whole.

«We have to drive ourselves to open our eyes, look at all the factors going on around us, and understand where we need to be focusing our time, effort and resources,» explained Mormino. «All of the issues we face today certainly have an environmental slant, but they impact us in so many different ways.» Brian Mormino, executive director — technical and environmental systems for Cummins. It’s impossible to accomplish anything by limiting activities to those occurring within an organization’s four walls. Reach out, said Mormino, and learn about the issues affecting them organizationally and the issues they are currently being forced to deal with on a societal level. Circle back, make additional commitments, foster additional partnerships and build on previous successes.

Planet 2050

Perhaps the most difficult question organizations grapple with related to sustainability is where, exactly, to start. And according to Mormino, two factors are at play when trying to come up with a definitive answer: foundation and belief.

«What is the culture and approach that exists within your organization?» asked Mormino. «And with that foundation comes the belief. And the belief is – when you look at the significant trends and issues around you – do you believe you can be part of the solution, for yourself and your organization, but also for society overall?»

2019 was the 100th anniversary of Cummins, and company officials marked the occasion by asking themselves the following question: If we’ve been around for 100 years, what do we need to do to stay around for 100 more?

Cummins eventually established an initiative known as Planet 2050, which serves to provide a framework for establishing goals and aspirational targets related to sustainability that extend out to the middle of this century. The initiative helps provide a roadmap for the company as it attempts to answer the questions “Where are we going?” and “What do we want to do?”

Aspirational targets

According to Mormino, the initiative is built around the following aspirational targets:

- Communities are better because we are there.

- A net positive impact in every community in which we operate

- Near-zero local environmental impact

- Doing our part on climate change and emissions.

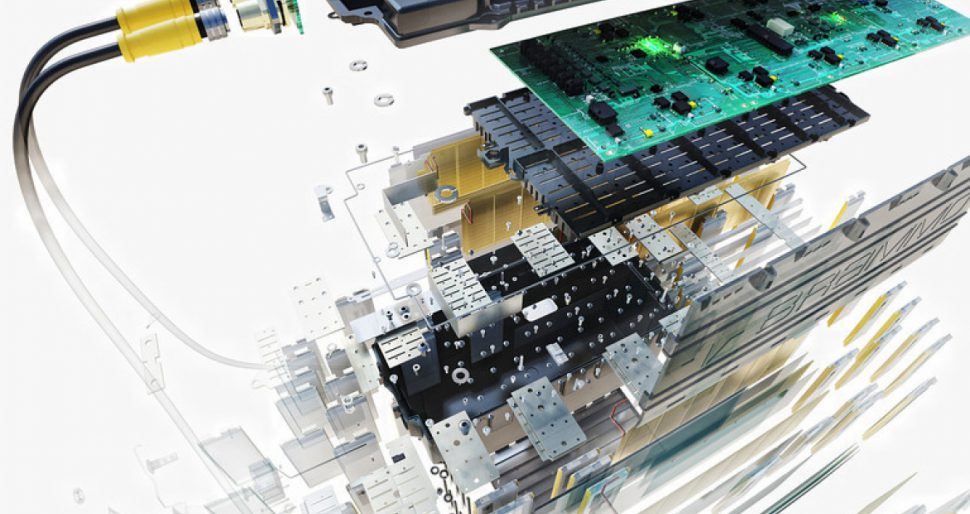

- Customer success powered by carbon-neutral technologies that address air quality

- Carbon neutrality and near-zero pollution in Cummins facilities and operations

- Using natural resources in the most sustainable way.

- Nothing wasted

- Use materials again for next life

- Reuse water and return clean to the community

«These aspirations, while strong and significant, they are achievable when you start to think about additive manufacturing, or you start to think about fuel cells,» said Mormino. «There are a variety of ways where you need to get out of your comfort zone and envision that world. However, in recognizing that 2050 is a ways out, you have to back it up. And that’s exactly what we did.»

With that in mind, Cummins established eight specific goals the company should achieve by 2030:

- Reduce greenhouse gas emissions from facilities and operations by 50 percent

- Reduce scope 3 absolute lifetime greenhouse gas emissions from newly sold products by 25 percent

- Partner with customers to reduce scope 3 greenhouse gas emissions from products in the field by 55 million tons

- Reduce volatile organic compound emissions from paint and coating operations by 50 percent

- Create a circular life plan for every part to use less, use better, or use again

- Generate 25 percent less waste in facilities and operations as part of revenues

- Reuse, or responsibly recycle, 100 percent of packaging plastics and eliminate single-use plastics in dining facilities, employee amenities and events

- Reduce absolute water consumption in facilities and operations by 30 percent