Carraro at Conexpo: through electric & hybrid

Carraro at Conexpo Las Vegas. Electric applications under the spotlight Carraro at Conexpo, In Las Vegas, the genuine industrial footprint of Carraro Drivetech and the North American construction industry are intertwined. Even in Carraro’s sights there is electrification. What the Italian manufacturer had to say to the audience at the Conexpo? Let’s hear it […]

Carraro at Conexpo Las Vegas. Electric applications under the spotlight

Carraro at Conexpo, In Las Vegas, the genuine industrial footprint of Carraro Drivetech and the North American construction industry are intertwined. Even in Carraro’s sights there is electrification. What the Italian manufacturer had to say to the audience at the Conexpo? Let’s hear it directly from their words.

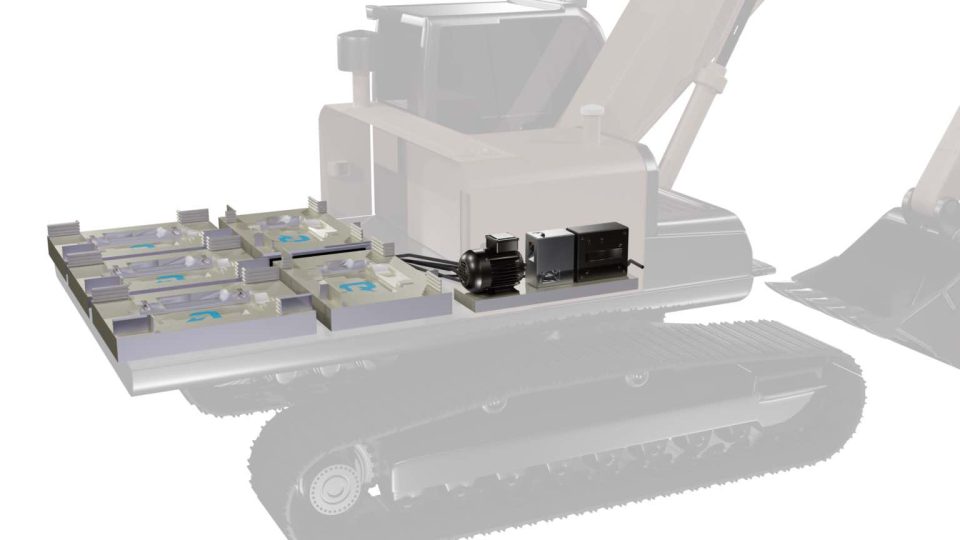

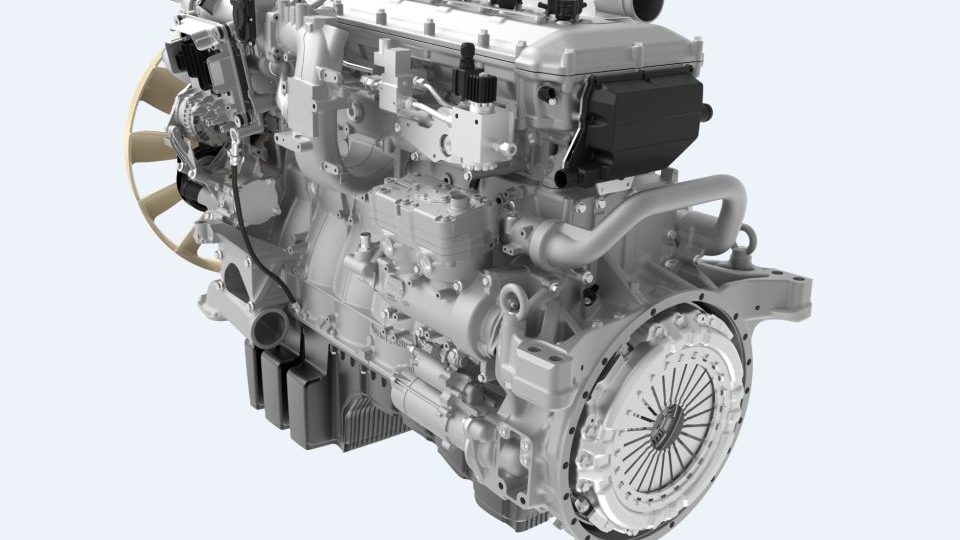

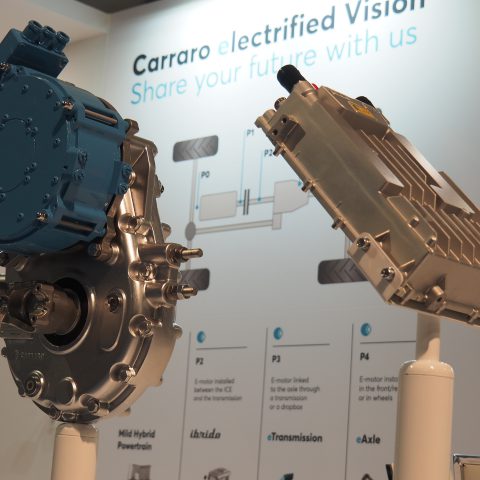

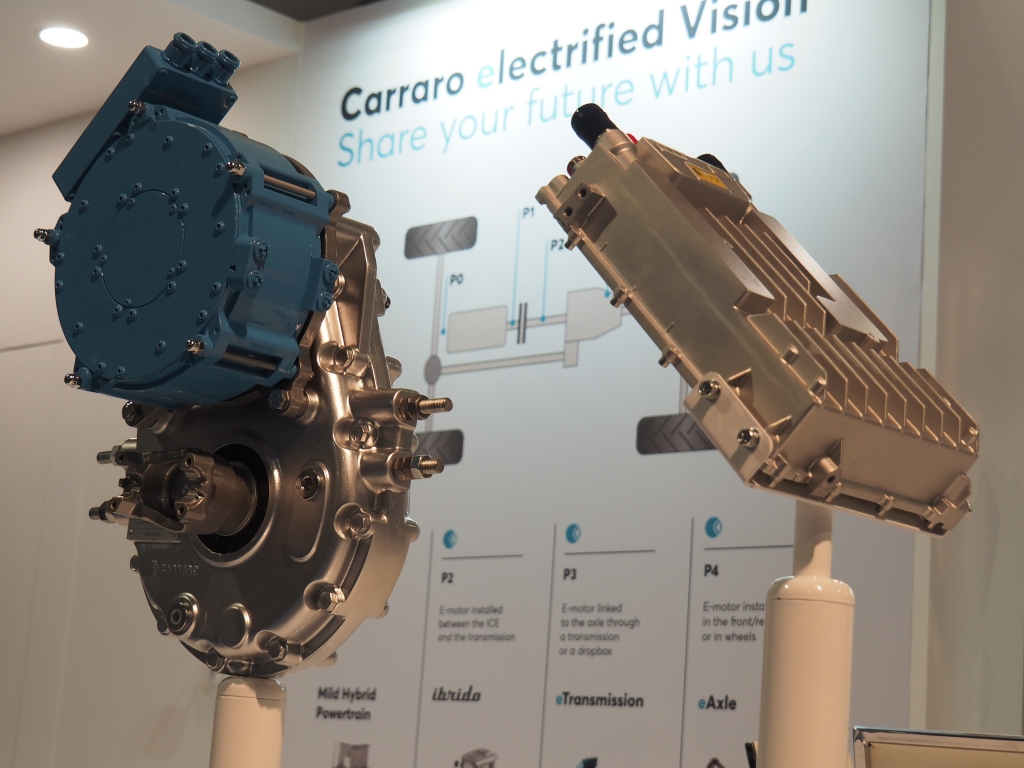

«Leveraging the 25 years of experience in development and supply of integrated drive systems for material handling applications for electric traction, Carraro more recently extended its portfolio to hybrid electric machines and electric powertrains. Now Carraro can offer the design of the whole system, combining its traditional mechanical know-how with strong electric/electronic competences. Able to support all the electric architecture topologies, Carraro is able to lead the complete e-powertrain through a dedicated ECU, then sizing and integrating the most suitable electric modules: from motors and generators, to inverters, batteries and battery management system to obtain the best performance for the entire system. Within a compact “tech-demo booth” in Las Vegas Carraro is displaying three main examples of its innovations both in terms of products and of service capabilities, highlighting its unique value proposition from the component to the complete machine.

At Carraro booth were on display the eTCH90 Long Drop / Torque Converter Full Powershift Transmission:designed to become Parallel Electric Hybrid unit. Suitable for several equal size tire machines, starting from tele boom handlers; the eTB220C / Gearbox specifically developed for full Electric Applications, able to have minimum power losses even at high input rotation speed and FLS 3.2 / Full powershift Hydrostatic Gearbox,able to fulfill the performance demand of several machines, ranging from small wheel loaders to tele boom handlers. All the gearboxes above are controlled by a software developed to run in the Carraro proprietary ECU, fully compliant with ISO 25119 (Functional Safety). Moreover, for all the powertrain applications Carraro can also enable to achieve further fuel efficiency and productivity through the simultaneous control of the whole powertrain (i.e. engine and transmission) thanks to its competence in developing control software to be injected in its proprietary Electronic Control Units. This year in the Carraro booth, thanks to a special Augmented Reality Tool, it is also possible to go more in deep with our technical solutions to better understand how we can fit them on different kind of applications. Our guests will be able to experience a real path through the Carraro know how in an unusual & involving interactive way.»