Interact Analysis: is ICE the way to hydrogen?

Alastair Hayfield, Senior Research Director of Interact Analysis, asked our questions about hydrogen and internal combustion engine. You can read the full article in the January-February issue of Powertrain.

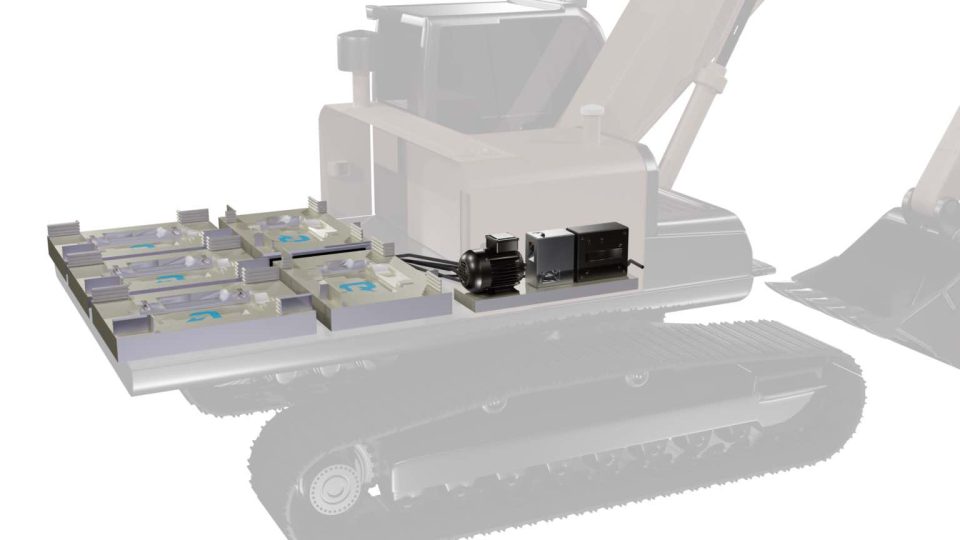

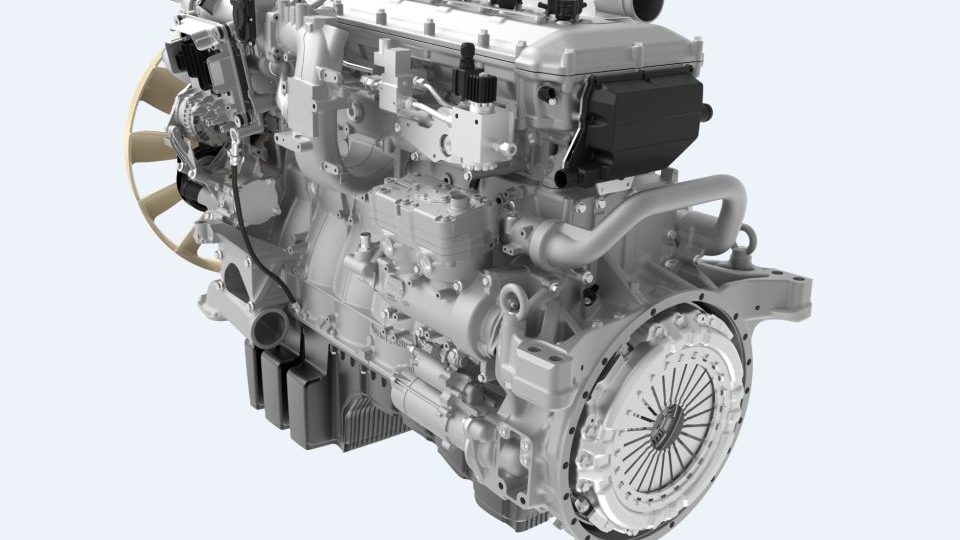

Hydrogen has hit the headlines. Its application with the ICE, according to some, could be its crowning achievement, ahead of the time expected by insiders. Alastair Hayfield, Senior Research Director of Interact Analysis, pondered if this makes sense. He pointed out that “JCB announced in May that it would be developing such a solution. And hot on the heels of this news we have seen Cummins, Caterpillar, Liebherr and the GAC Group make announcements that they too will be trialing and developing hydrogen combustion engines for a variety of applications. A hydrogen fueled combustion engine works in much the same way as a diesel fueled combustion engine. Hydrogen is combusted to produce water with no carbon-based emissions; however, the temperature of the reaction produces nitrogen oxides, which are harmful to human health. In addition to emissions and the costs associated with minimizing them, a “regular” combustion engine designed to use diesel needs to be modified to run on hydrogen, adding further cost. Additionally, a weighty set of high-pressure hydrogen tanks must be added to the vehicle, further increasing cost and decreasing the cargo payload. The current cost of hydrogen means that, not only is the engine/vehicle more expensive, but it costs substantially more to run – not something that is mentioned in the slick PR and marketing behind these projects. Proponents of the technology will argue that the cost of hydrogen will decrease with scale (true, but on a timeline of 5-10 years) and that “electrified” powertrains – battery or fuel cell – cost substantially more upfront. On this latter point, that is true right now, our research at Interact Analysis shows that both the battery and the fuel cell system are falling in price substantially over the next 5 or 10 years. Not only will this bring the purchase price of an electrified powertrain much closer to parity with an internal combustion engine powertrain, but with the substantially lower running costs associated with electricity, the total cost of ownership will be lower – for battery electric systems, at least”.

These are the assumptions. POWERTRAIN and Sustainabletruckvan.com asked Alastair to answer their questions.

There were a lot of expectations about the COP26, but it was totally disappointing. After the COP26, what’s your opinion about the internal combustion engine fueled by hydrogen as a transition technology?

I think it can work but there are a number of challenges to face. All the manufacturers and OEMs will have to develop their engines, road test them and it will take time: we won’t see their engines rolling out of production in 2022, we’re looking in a something long-term. Realistically, it will take at least three years before this technology enters the market in meaningful volumes. However, we have to face the challenge of emissions. I wonder if this technology will be beaten or maybe overtaken by other solutions, i.e. fuel cells. I don’t think there is a clear path towards electrifying agriculture machinery particularly quickly; we know that truck manufacturers are looking to biofuels, synthetic diesel, which are a lot easier to use with car engines because there is no real change in how you distribute it and store it. We think hydrogen doesn’t pollute but at the moment most hydrogen is not green, it’s brown and there’s still a carbon footprint associated with it. For me, there are still many issues to be resolved in this technology that sounds very promising: there are technical challenges and market challenges.