Kohler approves use of HVO for all its diesel engines in Europe

Kohler recently approved use of HVO for its diesel engines: it will enable a reduction in CO2 emissions of up to 90%, with no engine modifications needed

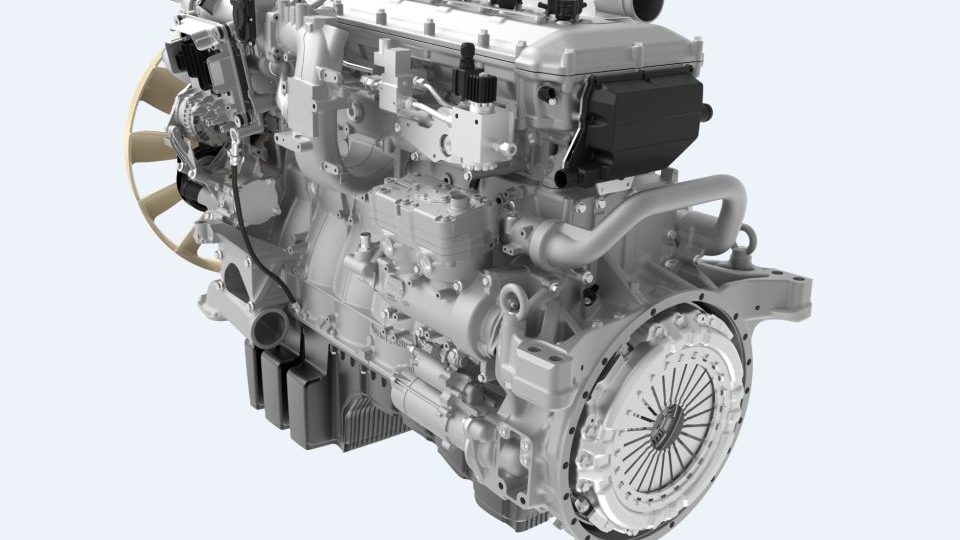

Kohler Engines recently approved use of EN15940-compliant Hydrotreated Vegetable Oils, or HVOs, for all its diesel engines – either pure or as a blend with conventional diesel. The approval came after intensive laboratory and on-the-field testing by Kohler’s engineering team. The group’s diesel engines do not require any kind of modification or specific upgrade to use HVO. However, use of exhaust gas after-treatment systems will still be necessary where already required.

HVO is a renewable paraffinic fuel also known under the names “synthetic diesel” and “renewable diesel”. It is produced with plant or animal oils derived from the residues of the meat and fish industries. Since it is obtained from organic material, HVO – unlike biodiesel – does not use agricultural resources or contributes to deforestation. It can be used wherever diesel fuel is used today. A reduction in overall CO2 emissions of up to 90% can be obtained depending on the raw material employed in HVO production. What’s more, compared to most conventional diesel fuels, HVO has an exceptionally low sulfur content and its use leads to lower vehicle exhaust emissions. Synthetic diesel is widely available in-service stations across northern Europe and is taking hold as the next-generation fuel. It is 100% fossil free and 100% recycled.

HVO fuel can be distributed, handled, and stored just like any conventional fuel. Pure or blended, it can be used in any Kohler engine, whether liquid-cooled from the KDI and KDW lines or air-cooled from the KD line. In addition, no variations to the maintenance schedule are required and normal European warranty conditions apply.

The future of HVO according to Kohler Engines

“We are witnessing a growing interest from customers for use of synthetic fuel (HVO) and other renewable fuels. eFuels are especially interesting, not only for their positive environmental impact but also because they reach performance levels comparable to diesel fuels,” stated Luigi Arnone, Senior Manager of Diesel Engine Engineering at Kohler (in the opening picture), adding that “HVO is a stable fuel that doesn’t require any engine modifications or additional maintenance.”

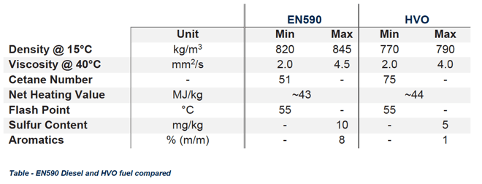

HVO fuel has a lower density, meaning that the mass of fuel injected per cycle is lower than that of EN590 diesel, reducing power and torque performance by 1 and 5%. This effect is partly compensated by a higher cetane number (75 for HVO vs. 51 for EN590 Diesel), which translates into positive effects on combustion.

Use of renewable fuels is one of the essential requirements to reach global decarbonization targets. With approval of HVO fuels for all its diesel models, Kohler is making its contribution to a more sustainable future.