Landini Evolving Hybrid: REX4 awarded by EIMA International

Landini Evolving Hybrid. Eima International has accustomed us to previews of hybrids for agricultural applications, not exceeding 100 kilowatts. Two years ago it was the turn of Carraro Ibrido, with the collaboration of TCD2.2 of Deutz and 4e-Consulting, for the electrical architecture. Probably the Diesel engine is still Deutz. Landini Evolving Hybrid. REX (King) at […]

Landini Evolving Hybrid. Eima International has accustomed us to previews of hybrids for agricultural applications, not exceeding 100 kilowatts. Two years ago it was the turn of Carraro Ibrido, with the collaboration of TCD2.2 of Deutz and 4e-Consulting, for the electrical architecture. Probably the Diesel engine is still Deutz.

Landini Evolving Hybrid. REX (King) at EIMA too

We report from Italian OEM.

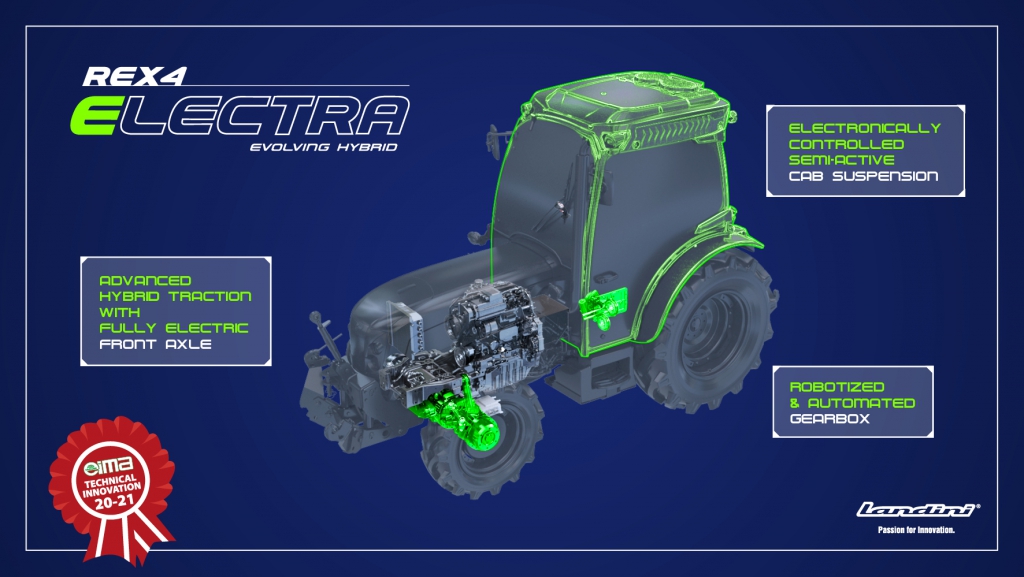

“The prestigious Eima International Novità Tecnica award still speaks Landini.

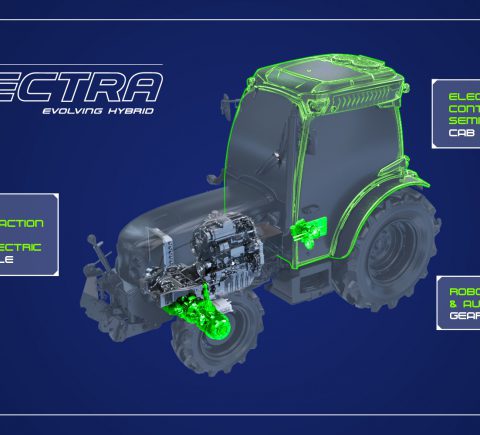

After winning the award in 2018 with the Advanced Driving System, the Argo Tractors group is once again awarded thanks to the Electra system – Evolving Hybrid – also intended for Landini REX4, which will be the protagonist both at Eima Digital, the preview scheduled on a web platform from 11 to 15 November, and at the 2021 physical edition of Eima, scheduled from 3 to 7 February at the Bologna Fiere pavilions.

The words of the Innovation Director of Argo Tractors

«For Argo Tractors it is an important recognition that rewards the great commitment and investment in research and development, which allow us to achieve cutting-edge levels of technological development for our tractors» comments with satisfaction the news of the award received by Giovanni Esposito, Innovation Director of Argo Tractors. «The evolution of our products provides customers with the most innovative solutions optimizing productivity and improving the quality of work, with the utmost attention that we have always paid to the human factor. From this point of view, the Electra system – Evolving Hybrid – has been designed to further increase the manoeuvrability, comfort and ease of use of REX4 tractors, responding to the needs of modern customers, guaranteeing cost-effectiveness and always keeping the attention to the environment and sustainability among the primary goals, through the use of new technologies». Specialized tractor for orchards and vineyards, Landini REX4 is already a tractor renowned for its manoeuvrability and ease of use, not separated from a formidable operating economy, thus fully meeting the needs of the most demanding customers. To these qualities are added solutions that also look to increase the efficiency of the tractor system and further improve life on board during long hours of use.

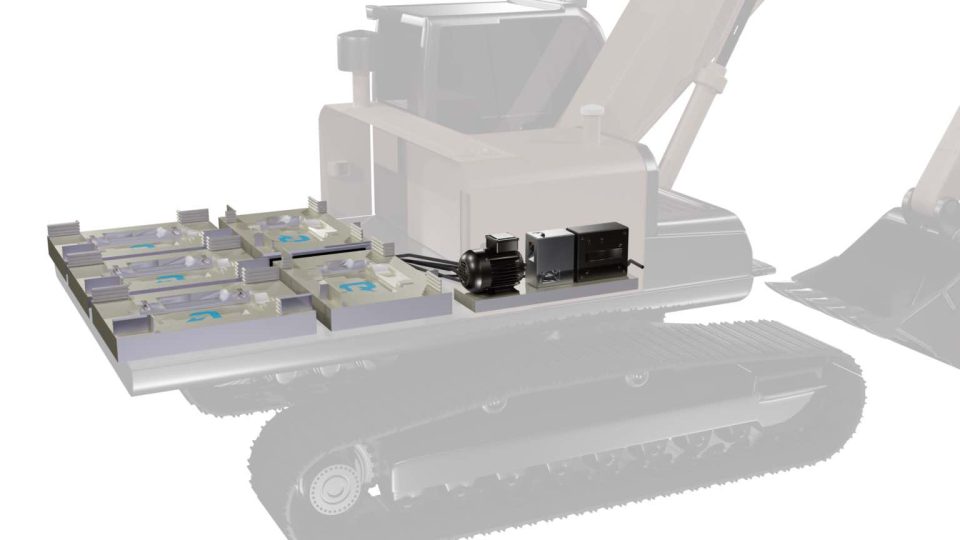

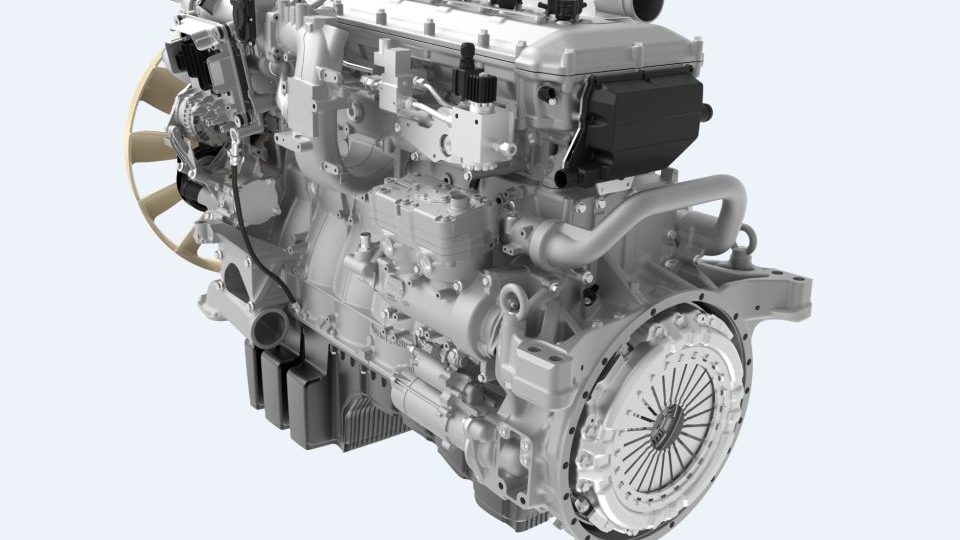

Landini REX4 Electra – Evolving Hybrid, therefore, features an innovative electric front wheel drive with independent wheels, Brake Energy Recovery, a cabin with electronically controlled semi-active suspension and a robotised gearbox for speed selection via joystick. Argo Tractors has developed both the mechanical and electrical components of this original project. REX4 Electra is powered by a 80,8 kW (110 hp) Diesel engine, Reverse Power Shuttle transmission and 3-speed Power Shift (HML).

Among the most important innovations is the fully electric front wheel drive on suspended axle, with two independent electric motors and related sensors, electronic controls, generator and battery dedicated to energy recovery during braking and deceleration. The entire system is managed by the PMS (Power Management System), which manages the operation of all devices, including the battery and, via the respective inverters, manages the motor and generator. This modern approach has made it possible to create a hybrid tractor where the Diesel engine, via generator and battery, powers the front electric motors, dialoguing continuously with the traditional mechanical matrix rear gearboxes, creating a parallel hybrid and making the system independent of the mechanical ratio between the tractor’s rear and front wheels.

10% fuel savings

The combination of technological improvements guarantees fuel savings of 10%, an improvement in steering angle of 15% and greater stability in transport, fully integrating with the current electric steering system.

To increase comfort, a new electronically controlled cab suspension has been included, thanks to a semi-active system similar to that already available on high-end product families. Suspended on four points, the cabin is equipped with two passive front suspension, while the rear has two hydraulic dampers with vibration reduction (anti-damping) governed by an electric signal. A control unit, which detects tractor movement and rough ground, regulates damping in real time and continuously. Here too, we can speak of a hybrid system, a fair compromise between ‘soft’ behaviour to absorb vibrations and ‘rigid’ to prevent the cab from hitting the travel limiters.

15% reduction in vibrations

The improvement in comfort is therefore clearly perceptible both in the field and in road transport, with a 15% reduction in the vibrations to which the driver is subjected. On the transmission side, the robotized gearbox that drives the gearbox rods via actuators is also indicated. A multifunction joystick in the cab replaces the traditional speed lever. The electronic control unit (ECU) receives the gearbox from the joystick and is informed of the status of the vehicle by sensors; when the conditions for speed change are met, the ECU controls the actuators that move the gearbox.”