Scania introduces 13-litre gas engine

Scania is renowned for its wide range of low-carbon powertrain options, and is now proud to add the all-new 13-litre gas engine that can run on natural gas and on biogas as well as new tank options.

The new Scania 13-litre gas engine enables travel operators to take huge steps towards sustainability. “Our 13-litre gas engine and new tank options facilitate travel operators to switch to biogas without issues with range and while still providing the power needed for any operation. Another upside is that it doesn’t take a huge investment,” says Jonas Strömberg, Sustainability Director, Scania Buses & Coaches.

Currently, biogas is used in compressed form mainly by city and suburban buses, cars and light transport vehicles, but has been less competitive for heavy long-distance vehicles. In recent years, technology that enables to cool the biogas, turning it into liquid and more energy-dense is available. This enables using the gas for heavy transport. The new engine and tank options make that a reality for Scania coaches. “Biogas will be one of the key tools for decarbonisation of heavy duty transport – especially for intercity and long-distance operations. Half of Europe’s heavy duty gas fleet could be powered by biogas in 2025,” says Strömberg. The expansion of tank infrastructure for liquified gas in Europe is also ongoing.

By switching to locally produced liquid biogas as fuel, operators can reduce both their own and their customers’ climate impact by up to 90 percent. Air quality in general is positively affected by reduced emissions, and the quieter vehicles benefit drivers, passengers and crew. With the possibility to use liquified gas and with the new tank options, the range achieved will be enough for any travel operation.The powertrain combination also makes it possible to build coaches in the same way as has previously been done with diesel engines.

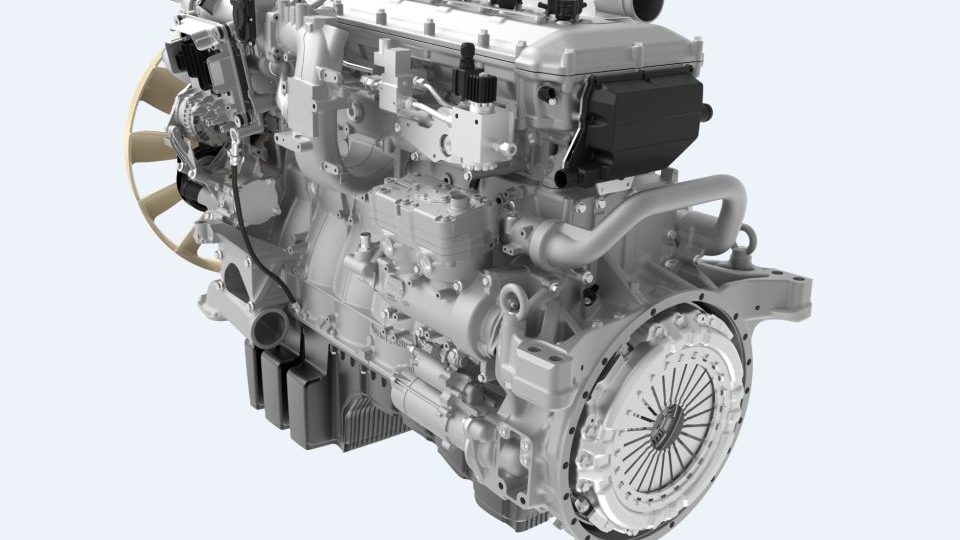

The 13-litre engine technical features

Moreover, the 13-litre engine offers the power and torque of equivalent diesel engines, meaning it can handle even the toughest challenges. This makes it the most sustainable, yet viable powertrain option on the market for long-distance operators. Furthermore, Scania gas engines require no additives to use the fuel, eliminating dependence on the additive’s availability, all while reducing operating costs.

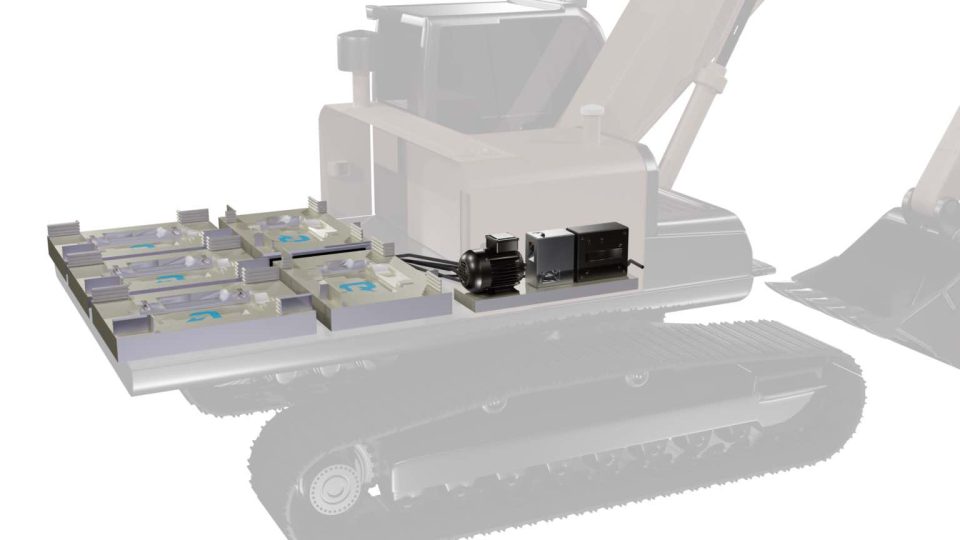

The 13-litre gas engine is available as an option on the recently introduced high-floor Scania K-chassis. The new chassis offer the great driveability and reliability associated with Scania, along with an increase in load capacity in the front axle by 500 kilos, which enables improved weight distribution and higher passenger and luggage capacity. The chassis also come with newly developed suspension for improved comfort, a new first-class driver area, as well as added safety features and advanced driver assistance systems. In addition, they offer significant fuel consumption reductions without compromising on performance – and are compatible with new data-driven services that help increase both uptime and safety.