Kohler gets Stage V Certification

Kohler: Stage V certfication for the diesel range Kohler is growing up in the OEM’s providers scenario, designing and manufacturing diesel engines for off-road applications: the latest milestone it has reached is Stage V certification for KDI engines in the 19-56 kW power range. THE KOHLER CEO, MR PERRONE, SAID… Thanks to the partnership with […]

Kohler: Stage V certfication for the diesel range

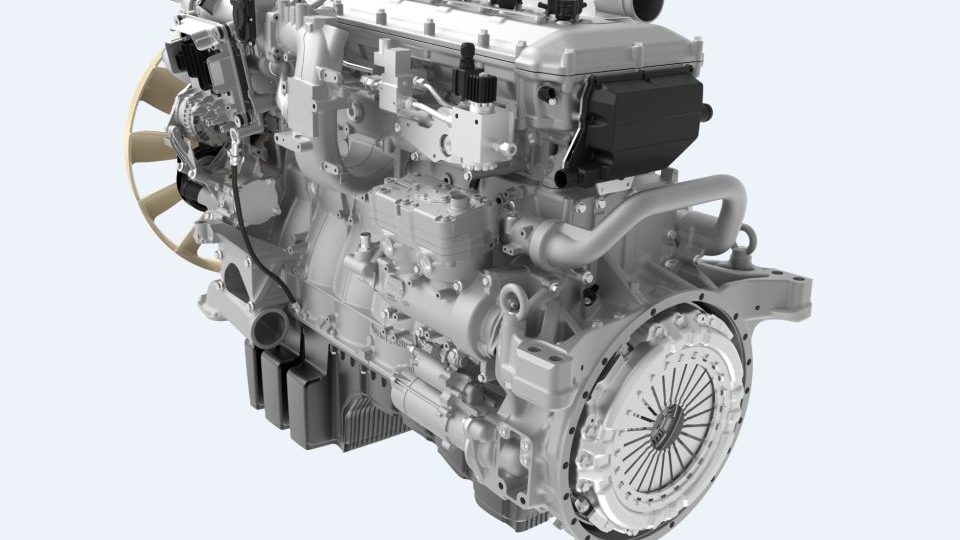

Kohler is growing up in the OEM’s providers scenario, designing and manufacturing diesel engines for off-road applications: the latest milestone it has reached is Stage V certification for KDI engines in the 19-56 kW power range.

THE KOHLER CEO, MR PERRONE, SAID…

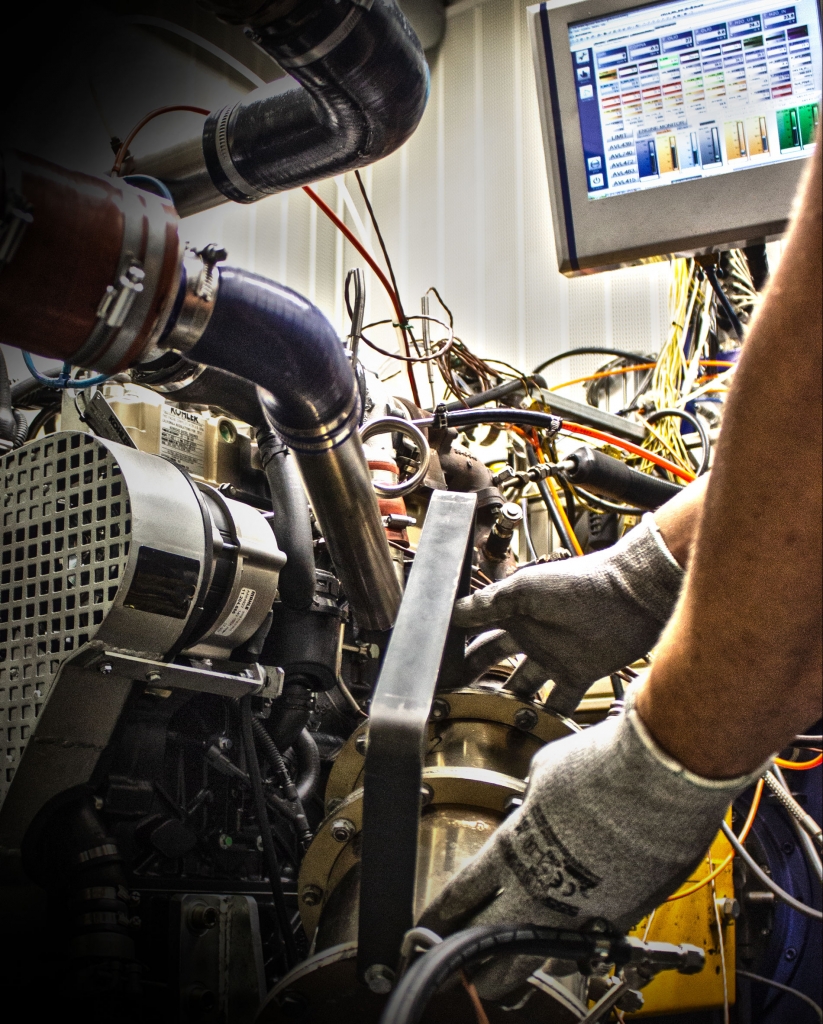

Thanks to the partnership with one of the agencies accredited to the European Union for the certification of internal combustion engines, the first half of 2018 was devoted to tests and analysis on the company’s range of diesel engines with the aim of verifying their compliance with all the requisites indicated by the legislator.

To properly comply with the requirements for this certification, the only possible solution is to adopt a diesel particulate filter (DPF), representing a huge challenge for all manufacturers of diesel engines. Kohler recognised this opportunity immediately, developing after-treatment solutions that are ideal for machine manufacturers and for the end user.

Like announced, Stage V will start January 2019

The certification of the range of diesel engines is confirmation of the announcement made by Vincenzo Perrone, President of Diesel Engines, during the press conference at Agritechnica 2017: «The challenge for engine manufacturers has been to develop a flexible solution capable of responding to the many different needs on the market. At Kohler, we took up and won the challenge thanks to the competitive edge of the Kohler Kdi range of engines: as a result, we are proud to present the Kohler Flex range of solutions for filtering emissions that was designed by Kohler so that any Kdi engine configuration can be compliant with all the standards and regulations on emissions anywhere in the world».

The production line of Stage V certified engines will start, as announced, on January 1st 2019, in line with European Union directives and answering the needs of manufacturers of off-road applications.

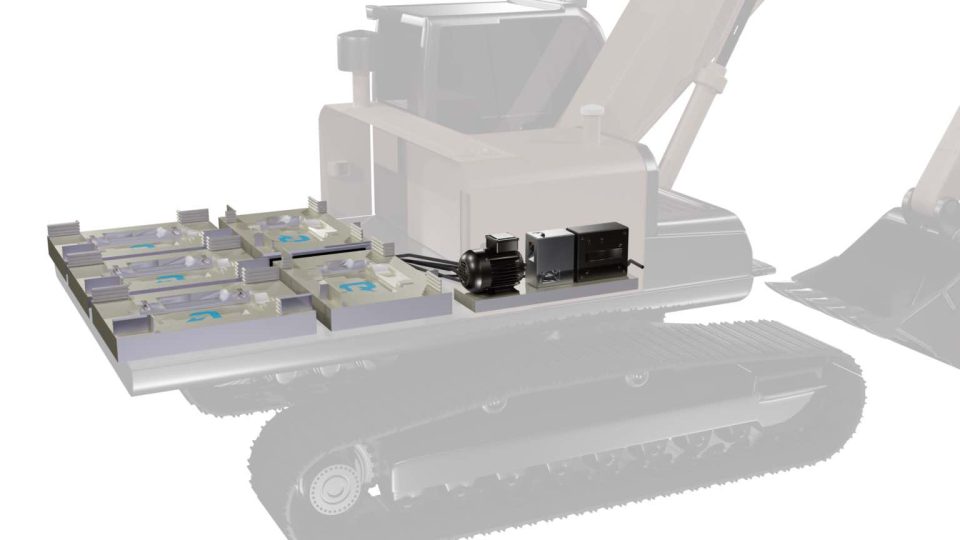

Kohler’s post-treatment systems

Thanks to the all-in-one configuration of Kohler’s after-treatment systems, manufacturers will be able to make best use of small footprints during the installation due to the very compact design of post-treatment systems. At the same time, the end user will be able to benefit from the regeneration stage that will be totally transparent and will not have any impact on productivity and the efficiency of the machine.

Stage V certification was obtained by the entire range of diesel engines up to 56 kW, which were displayed at the Kohler stand at EIMA 2018.