Wärtsilä builds plant for the production of Bio-LNG

Wärtsilä will supply equipment for the world’s second-largest plant capable of liquefying bio-methane and synthetic methane from renewable energy sources to produce carbon-neutral transportation fuel.

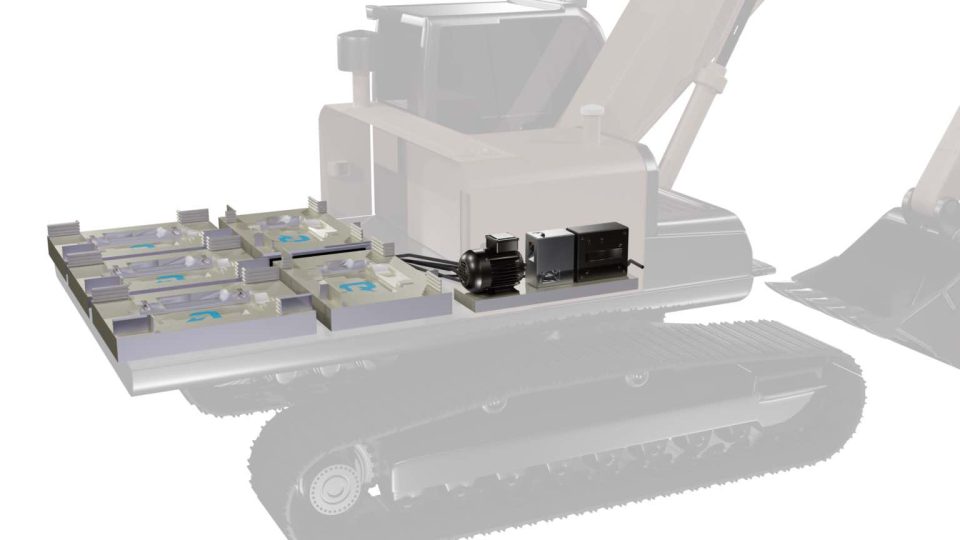

Wärtsilä will supply equipment for the world’s second-largest plant capable of liquefying bio-methane and synthetic methane from renewable energy sources to produce carbon-neutral transportation fuel. When operational it will have a capacity of approximately 63,000 tons Bio-LNG per year. The contract was placed in March 2022 by the German energy company Reefuelery – a joint venture of Erdgas Südwest and avanca, a company focused on sustainable energy and logistics solutions.

The plant will be located in Burghaun near Fulda, Germany. Burghaun was chosen as the preferred location for this project due to its direct access to the Midal, one of the most powerful gas pipelines in Germany. The central location enables optimum supply to the Alternoil filling stations – owned by the avanca group.

Wärtsilä: bio-methane for decarbonization

The plant will utilise biomethane from communal and agricultural waste materials as feedstock. The biomethane is subsequently liquefied and delivered to the Alternoil filling station network as the climate-neutral fuel Reefuel (Bio-LNG).

“Reefuel can be used in any LNG-fuelled truck and contributes significantly to the decarbonisation of heavy-duty transport. The construction of the liquefaction plant will reduce CO2 emissions along the entire supply chain, thereby effectively using economies of scale,” said Jürgen Muhle, CEO of the avanca group.

“Wärtsilä has already been a valuable partner in other projects. We are very pleased that we can now once again draw on Wärtsilä’s extremely precious expertise for the Reefuelery,” says Frank Erben, Managing Director of Reefuelery and Investment Manager of Erdgas Südwest.

“Decarbonisation solutions are at the front and centre of Wärtsilä’s strategies, and we are delighted to support Reefuelery in the realisation of their first German biomethane liquefaction plant. It is a prime circular economy model. Our unmatched in-house expertise and vast experience in the process design, engineer, fabrication, and delivery of gas liquefaction plants, as well as mature gas treatment solutions prior to liquefaction, form a solid foundation for building a sustainable future,” commented Walter Reggente, Vice-President, Wärtsilä Gas Solutions.

The plant is expected to become fully operational during the first quarter of 2024.